–Х—Б–ї–Є –≤—Л —Е–Њ—В–Є—В–µ —Б–і–µ–ї–∞—В—М –њ—А–∞–≤–Є–ї—М–љ—Л–є –≤—Л–±–Њ—А –і–ї—П —Б–≤–Њ–µ–≥–Њ —Б–ї–µ–і—Г—О—Й–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –≤—Л–і–µ–ї—П—О—В—Б—П —Б–≤–Њ–µ–є –ї–µ–≥–Ї–Њ—Б—В—М—О, –њ—А–Њ—З–љ–Њ—Б—В—М—О, –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М—О –Є —Г–љ–Є–≤–µ—А—Б–∞–ї—М–љ–Њ—Б—В—М—О. –Р–ї—О–Љ–Є–љ–Є–є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –±–Њ–ї—М—И—Г—О –≥–Є–±–Ї–Њ—Б—В—М –≤ –њ—А–Њ–µ–Ї—В–Є—А–Њ–≤–∞–љ–Є–Є –Є –њ—А–Њ—Б—В –≤ –Њ–±—А–∞–±–Њ—В–Ї–µ. –Т—Л –Љ–Њ–ґ–µ—В–µ –љ–∞—Б—В—А–∞–Є–≤–∞—В—М —Д–Њ—А–Љ—Л –Є –Њ—В–і–µ–ї–Ї—Г –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б–Њ —Б–≤–Њ–Є–Љ–Є –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ–Є. –Т –Њ—В–ї–Є—З–Є–µ –Њ—В —Б—В–∞–ї–Є, –Ї–Њ—В–Њ—А–∞—П —В—П–ґ–µ–ї–∞ –Є —В—А–µ–±—Г–µ—В –±–Њ–ї—М—И–µ–≥–Њ —Г—Е–Њ–і–∞, –Є–ї–Є –і–µ—А–µ–≤–∞, –Ї–Њ—В–Њ—А–Њ–µ –Љ–µ–љ–µ–µ –њ—А–Њ—З–љ–Њ –Є —З–∞—Б—В–Њ —В—А–µ–±—Г–µ—В —А–µ–Љ–Њ–љ—В–∞, –∞–ї—О–Љ–Є–љ–Є–є –њ—А–µ–і–ї–∞–≥–∞–µ—В –њ—А–∞–Ї—В–Є—З–љ–Њ–µ —А–µ—И–µ–љ–Є–µ. –Т—Л–±–Њ—А –њ—А–∞–≤–Є–ї—М–љ–Њ–≥–Њ –Љ–∞—В–µ—А–Є–∞–ї–∞ –Њ–Ј–љ–∞—З–∞–µ—В —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–µ –µ–≥–Њ —Е–∞—А–∞–Ї—В–µ—А–Є—Б—В–Є–Ї —В—А–µ–±–Њ–≤–∞–љ–Є—П–Љ –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞.

–Ю—Б–љ–Њ–≤–љ—Л–µ –≤—Л–≤–Њ–і—Л

-

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –ї–µ–≥–Ї–Є–µ –Є –њ—А–Њ—З–љ—Л–µ, —З—В–Њ –і–µ–ї–∞–µ—В –Є—Е —Г–і–Њ–±–љ—Л–Љ–Є –≤ –Њ–±—А–∞—Й–µ–љ–Є–Є –Є –Љ–Њ–љ—В–∞–ґ–µ –і–ї—П —А–∞–Ј–ї–Є—З–љ—Л—Е —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤.

-

–Ю–љ–Є –Њ–±–ї–∞–і–∞—О—В –њ—А–µ–≤–Њ—Б—Е–Њ–і–љ–Њ–є –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ–є —Б—В–Њ–є–Ї–Њ—Б—В—М—О –Є –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М—О, –Њ—Б–Њ–±–µ–љ–љ–Њ –њ—А–Є —В–∞–Ї–Є—Е –≤–Є–і–∞—Е –Њ–±—А–∞–±–Њ—В–Ї–Є –њ–Њ–≤–µ—А—Е–љ–Њ—Б—В–Є, –Ї–∞–Ї –∞–љ–Њ–і–Є—А–Њ–≤–∞–љ–Є–µ –Є –љ–∞–љ–µ—Б–µ–љ–Є–µ –њ–Њ–Ї—А—Л—В–Є–є.

-

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—В –≥–Є–±–Ї–Њ—Б—В—М –њ—А–Њ–µ–Ї—В–Є—А–Њ–≤–∞–љ–Є—П, –њ–Њ–Ј–≤–Њ–ї—П—П –Є–Ј–Љ–µ–љ—П—В—М —Д–Њ—А–Љ—Г –Є –Њ—В–і–µ–ї–Ї—Г –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ–Є –њ—А–Њ–µ–Ї—В–∞.

-

–Т—Л–±–Њ—А –∞–ї—О–Љ–Є–љ–Є—П –њ–Њ–Ј–≤–Њ–ї—П–µ—В —Б—Н–Ї–Њ–љ–Њ–Љ–Є—В—М –љ–∞ –і–Њ–ї–≥–Њ—Б—А–Њ—З–љ—Л—Е –Ј–∞—В—А–∞—В–∞—Е –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –±–ї–∞–≥–Њ–і–∞—А—П –љ–Є–Ј–Ї–Є–Љ —В—А–µ–±–Њ–≤–∞–љ–Є—П–Љ –Ї —Г—Е–Њ–і—Г –њ–Њ —Б—А–∞–≤–љ–µ–љ–Є—О —Б –і–µ—А–µ–≤–Њ–Љ –Є —Б—В–∞–ї—М—О.

-

–Р–ї—О–Љ–Є–љ–Є–є —Е–Њ—А–Њ—И–Њ –њ–Њ–і–і–∞–µ—В—Б—П –њ–µ—А–µ—А–∞–±–Њ—В–Ї–µ, —З—В–Њ –і–µ–ї–∞–µ—В –µ–≥–Њ —Н–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —З–Є—Б—В—Л–Љ –≤—Л–±–Њ—А–Њ–Љ, —Б–њ–Њ—Б–Њ–±—Б—В–≤—Г—О—Й–Є–Љ –≤–љ–µ–і—А–µ–љ–Є—О —Г—Б—В–Њ–є—З–Є–≤—Л—Е –Љ–µ—В–Њ–і–Њ–≤ —Б—В—А–Њ–Є—В–µ–ї—М—Б—В–≤–∞.

–Ю–±–Ј–Њ—А –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАУ —Н—В–Њ –Љ–∞—В–µ—А–Є–∞–ї, –Њ–±–ї–∞–і–∞—О—Й–Є–є –Љ–љ–Њ–ґ–µ—Б—В–≤–Њ–Љ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤. –Р–ї—О–Љ–Є–љ–Є–µ–≤–∞—П —Н–Ї—Б—В—А—Г–Ј–Є—П –њ–Њ–Ј–≤–Њ–ї—П–µ—В —Б–Њ–Ј–і–∞–≤–∞—В—М –ї–µ–≥–Ї–Є–µ –Ї–Њ–Љ–њ–Њ–љ–µ–љ—В—Л, —Г–і–Њ–±–љ—Л–µ –≤ –Њ–±—А–∞—Й–µ–љ–Є–Є –Є –Љ–Њ–љ—В–∞–ґ–µ. –Я—А–Є —Н—В–Њ–Љ –і–Њ—Б—В–Є–≥–∞–µ—В—Б—П –≤–њ–µ—З–∞—В–ї—П—О—Й–∞—П –њ—А–Њ—З–љ–Њ—Б—В—М –±–µ–Ј –≥—А–Њ–Љ–Њ–Ј–і–Ї–Њ—Б—В–Є —Б—В–∞–ї–Є. –≠—В–Њ –і–µ–ї–∞–µ—В –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Є–і–µ–∞–ї—М–љ—Л–Љ–Є –Ї–∞–Ї –і–ї—П –∞—А—Е–Є—В–µ–Ї—В—Г—А–љ—Л—Е, —В–∞–Ї –Є –і–ї—П –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ—Л—Е —Ж–µ–ї–µ–є. –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Љ–Њ–ґ–љ–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞—В—М –і–ї—П –Њ–Ї–Њ–љ–љ—Л—Е —А–∞–Љ, –і–≤–µ—А–µ–є, –љ–∞–≤–µ—Б–љ—Л—Е —Д–∞—Б–∞–і–Њ–≤ –Є –і–∞–ґ–µ –≤–љ—Г—В—А–µ–љ–љ–µ–є –Њ—В–і–µ–ї–Ї–Є.

–Ъ–Њ–Љ–њ–∞–љ–Є—П Guang Ya Aluminium Industries Co., Ltd. –Ј–∞—А–µ–Ї–Њ–Љ–µ–љ–і–Њ–≤–∞–ї–∞ —Б–µ–±—П –Ї–∞–Ї –љ–∞–і–µ–ґ–љ—Л–є –њ–Њ—Б—В–∞–≤—Й–Є–Ї –≤—Л—Б–Њ–Ї–Њ–Ї–∞—З–µ—Б—В–≤–µ–љ–љ—Л—Е –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є, –Є–Ј–≥–Њ—В–∞–≤–ї–Є–≤–∞–µ–Љ—Л—Е –њ–Њ –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ—Л–Љ –Ј–∞–Ї–∞–Ј–∞–Љ. –Р—Б—Б–Њ—А—В–Є–Љ–µ–љ—В –њ—А–Њ–і—Г–Ї—Ж–Є–Є –≤–Ї–ї—О—З–∞–µ—В –≤ —Б–µ–±—П –≤—Б–µ, –Њ—В...

–Я—А–Њ–Љ—Л—И–ї–µ–љ–љ—Л–µ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є

–Ї –∞—А—Е–Є—В–µ–Ї—В—Г—А–љ—Л–Љ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–Љ –њ—А–Њ—Д–Є–ї—П–Љ. –С–ї–∞–≥–Њ–і–∞—А—П —А–∞—Б—И–Є—А–µ–љ–љ—Л–Љ –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—П–Љ –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ–Њ–є –љ–∞—Б—В—А–Њ–є–Ї–Є –≤—Л –Љ–Њ–ґ–µ—В–µ –њ—А–Њ–µ–Ї—В–Є—А–Њ–≤–∞—В—М –њ—А–Њ—Д–Є–ї–Є, —В–Њ—З–љ–Њ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤—Г—О—Й–Є–µ –≤–∞—И–Є–Љ –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ.

–Т–Њ—В –Ї—А–∞—В–Ї–Њ–µ —Б—А–∞–≤–љ–µ–љ–Є–µ –∞–ї—О–Љ–Є–љ–Є—П —Б –і—А—Г–≥–Є–Љ–Є —Д–∞—Б–∞–і–љ—Л–Љ–Є –Љ–∞—В–µ—А–Є–∞–ї–∞–Љ–Є:

|

–°–≤–Њ–є—Б—В–≤–Њ

|

–Р–ї—О–Љ–Є–љ–Є–є

|

–Э–µ—А–ґ–∞–≤–µ—О—Й–∞—П —Б—В–∞–ї—М

|

|

–Я—А–µ–і–µ–ї –њ—А–Њ—З–љ–Њ—Б—В–Є –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ (–Ь–Я–∞)

|

100 - 400

|

515 - 1300

|

|

–Ъ–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–∞—П —Б—В–Њ–є–Ї–Њ—Б—В—М

|

–•–Њ—А–Њ—И–Є–є, –љ–Њ –Љ–µ–љ–µ–µ —Н—Д—Д–µ–Ї—В–Є–≤–µ–љ –≤ –∞–≥—А–µ—Б—Б–Є–≤–љ–Њ–є —Б—А–µ–і–µ.

|

–Т—Л–љ–Њ—Б–ї–Є–≤–Њ—Б—В—М –≤—Л—И–µ –≤ –∞–≥—А–µ—Б—Б–Є–≤–љ–Њ–є —Б—А–µ–і–µ.

|

|

–Ґ–µ–њ–ї–Њ–њ—А–Њ–≤–Њ–і–љ–Њ—Б—В—М (–Т—В/–Љ–Ъ)

|

–Т—Л—И–µ, —З–µ–Љ –љ–µ—А–ґ–∞–≤–µ—О—Й–∞—П —Б—В–∞–ї—М

|

–Э–Є–ґ–µ, —З–µ–Љ –∞–ї—О–Љ–Є–љ–Є–є

|

–С–ї–∞–≥–Њ–і–∞—А—П —Б–∞–Љ–Њ–Ј–∞—Й–Є—В–љ–Њ–Љ—Г –Њ–Ї—Б–Є–і–љ–Њ–Љ—Г —Б–ї–Њ—О –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–є –њ—А–Њ—Д–Є–ї—М –Њ–±–ї–∞–і–∞–µ—В —Е–Њ—А–Њ—И–µ–є –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ–є —Б—В–Њ–є–Ї–Њ—Б—В—М—О. –Т –±–Њ–ї—М—И–Є–љ—Б—В–≤–µ —Г—Б–ї–Њ–≤–Є–є –Њ–Ї—А—Г–ґ–∞—О—Й–µ–є —Б—А–µ–і—Л –≤–∞–Љ –љ–µ –љ—Г–ґ–љ–Њ –±–µ—Б–њ–Њ–Ї–Њ–Є—В—М—Б—П –Њ —А–ґ–∞–≤—З–Є–љ–µ. –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–є –њ—А–Њ—Д–Є–ї—М —В–∞–Ї–ґ–µ –Њ–±–ї–∞–і–∞–µ—В –≤—Л—Б–Њ–Ї–Њ–є —В–µ–њ–ї–Њ–њ—А–Њ–≤–Њ–і–љ–Њ—Б—В—М—О, —З—В–Њ —Б–њ–Њ—Б–Њ–±—Б—В–≤—Г–µ—В –њ–Њ–≤—Л—И–µ–љ–Є—О —Н–љ–µ—А–≥–Њ—Н—Д—Д–µ–Ї—В–Є–≤–љ–Њ—Б—В–Є —Д–∞—Б–∞–і–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤.

–Ю–±—А–∞–±–Њ—В–Ї–∞ –њ–Њ–≤–µ—А—Е–љ–Њ—Б—В–Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –µ—Й–µ –±–Њ–ї—М—И—Г—О –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є —Б—В–Є–ї—М–љ—Л–є –≤–Є–і. –Ю–Ј–љ–∞–Ї–Њ–Љ—М—В–µ—Б—М —Б –≤–∞—А–Є–∞–љ—В–∞–Љ–Є:

|

–Ґ–Є–њ –ї–µ—З–µ–љ–Є—П

|

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞

|

–£—А–Њ–≤–µ–љ—М –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В–Є

|

|

–Р–љ–Њ–і–Є—А–Њ–≤–∞–љ–Є–µ

|

–Ъ–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–∞—П —Б—В–Њ–є–Ї–Њ—Б—В—М, –Є–Ј–љ–Њ—Б–Њ—Б—В–Њ–є–Ї–Њ—Б—В—М, —Н—Б—В–µ—В–Є—З–µ—Б–Ї–∞—П —Г–љ–Є–≤–µ—А—Б–∞–ї—М–љ–Њ—Б—В—М

|

–Т—Л—Б–Њ–Ї–Є–є

|

|

–Я–Њ–Ї—А—Л—В–Є–µ

|

–≠—Б—В–µ—В–Є—З–µ—Б–Ї–∞—П –≥–Є–±–Ї–Њ—Б—В—М, —Н–Ї–Њ–љ–Њ–Љ–Є—З–љ–Њ—Б—В—М

|

–£–Љ–µ—А–µ–љ–љ—Л–є

|

|

–Я–µ—А–µ–љ–Њ—Б –і—А–µ–≤–µ—Б–љ—Л—Е –≤–Њ–ї–Њ–Ї–Њ–љ

|

–Х—Б—В–µ—Б—В–≤–µ–љ–љ—Л–є –≤–Є–і, —В—А–µ–±—Г–µ—В –і–Њ–њ–Њ–ї–љ–Є—В–µ–ї—М–љ–Њ–є –Ј–∞—Й–Є—В—Л.

|

–Э–Є–Ј–Ї–Є–є

|

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–є –њ—А–Њ—Д–Є–ї—М –њ–Њ–Ј–≤–Њ–ї—П–µ—В –≤—Л–±—А–∞—В—М –Њ—В–і–µ–ї–Ї—Г, —Б–Њ–Њ—В–≤–µ—В—Б—В–≤—Г—О—Й—Г—О –≤–∞—И–µ–Љ—Г –і–Є–Ј–∞–є–љ–µ—А—Б–Ї–Њ–Љ—Г –Ј–∞–Љ—Л—Б–ї—Г. –Р–љ–Њ–і–Є—А–Њ–≤–∞–љ–Є–µ –њ–Њ–≤—Л—И–∞–µ—В –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ—Г—О —Б—В–Њ–є–Ї–Њ—Б—В—М –Є –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М, –∞ –њ–Њ—А–Њ—И–Ї–Њ–≤–∞—П –њ–Њ–Ї—А–∞—Б–Ї–∞ –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –≥–Є–±–Ї–Њ—Б—В—М –≤ –≤—Л–±–Њ—А–µ —Ж–≤–µ—В–∞. –Т—Л –і–∞–ґ–µ –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М –Є–Љ–Є—В–∞—Ж–Є—О —В–µ–Ї—Б—В—Г—А—Л –і–µ—А–µ–≤–∞ –і–ї—П —Б–Њ–Ј–і–∞–љ–Є—П –µ—Б—В–µ—Б—В–≤–µ–љ–љ–Њ–≥–Њ –≤–Є–і–∞.

–°–Њ–≤–µ—В: –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є, –Є–Ј–≥–Њ—В–Њ–≤–ї–µ–љ–љ—Л–µ –Љ–µ—В–Њ–і–Њ–Љ —Н–Ї—Б—В—А—Г–Ј–Є–Є, —Е–Њ—А–Њ—И–Њ –њ–Њ–і–і–∞—О—В—Б—П –њ–µ—А–µ—А–∞–±–Њ—В–Ї–µ. –Т—Л–±–Є—А–∞—П –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –і–ї—П –Њ–±–ї–Є—Ж–Њ–≤–Њ—З–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤, –≤—Л –њ–Њ–Љ–Њ–≥–∞–µ—В–µ –Њ–Ї—А—Г–ґ–∞—О—Й–µ–є —Б—А–µ–і–µ.

–Э–µ–і–Њ—Б—В–∞—В–Ї–Є –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є

–£ —Н–Ї—Б—В—А—Г–Ј–Є–Є –∞–ї—О–Љ–Є–љ–Є—П –µ—Б—В—М –љ–µ–Ї–Њ—В–Њ—А—Л–µ –Њ–≥—А–∞–љ–Є—З–µ–љ–Є—П. –Т—Л –Љ–Њ–ґ–µ—В–µ –Ј–∞–Љ–µ—В–Є—В—М, —З—В–Њ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –љ–µ –Њ–±–ї–∞–і–∞—О—В —В–∞–Ї–Њ–є –ґ–µ –њ—А–Њ—З–љ–Њ—Б—В—М—О –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ, –Ї–∞–Ї —Б—В–∞–ї—М. –Т –∞–≥—А–µ—Б—Б–Є–≤–љ—Л—Е —Б—А–µ–і–∞—Е –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–∞—П —Б—В–Њ–є–Ї–Њ—Б—В—М –Љ–Њ–ґ–µ—В —Б–љ–Є–ґ–∞—В—М—Б—П, –Њ—Б–Њ–±–µ–љ–љ–Њ –µ—Б–ї–Є –љ–µ –њ—А–Њ–≤–Њ–і–Є—В—М –Њ–±—А–∞–±–Њ—В–Ї—Г –њ–Њ–≤–µ—А—Е–љ–Њ—Б—В–Є. –Э–µ—А–ґ–∞–≤–µ—О—Й–∞—П —Б—В–∞–ї—М —З–∞—Б—В–Њ –ї—Г—З—И–µ –њ—А–Њ—П–≤–ї—П–µ—В —Б–µ–±—П –≤ —Б–Є–ї—М–љ–Њ–Ї–Є—Б–ї–Њ—В–љ—Л—Е –Є–ї–Є —Й–µ–ї–Њ—З–љ—Л—Е —Б—А–µ–і–∞—Е.

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–є –њ—А–Њ—Д–Є–ї—М –ї–µ–≥—З–µ –і–µ—Д–Њ—А–Љ–Є—А—Г–µ—В—Б—П, —З–µ–Љ —Б—В–∞–ї—М–љ–Њ–є. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–љ–∞ –Љ–∞–Ї—Б–Є–Љ–∞–ї—М–љ–∞—П –њ—А–Њ—З–љ–Њ—Б—В—М –і–ї—П —В—П–ґ–µ–ї—Л—Е –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ—Л—Е —Г—Б–ї–Њ–≤–Є–є, –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ, —Б—В–Њ–Є—В —Б—А–∞–≤–љ–Є—В—М –≤–∞—А–Є–∞–љ—В—Л. –Ю—В–і–µ–ї–Ї–∞ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є –њ–Њ–і –і–µ—А–µ–≤–Њ –≤—Л–≥–ї—П–і–Є—В –≤–µ–ї–Є–Ї–Њ–ї–µ–њ–љ–Њ, –љ–Њ —В—А–µ–±—Г–µ—В –і–Њ–њ–Њ–ї–љ–Є—В–µ–ї—М–љ–Њ–≥–Њ —Г—Е–Њ–і–∞ –і–ї—П —Б–Њ—Е—А–∞–љ–µ–љ–Є—П –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В–Є.

–Ъ–Њ–≥–і–∞ —Б–ї–µ–і—Г–µ—В –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞—В—М –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є?

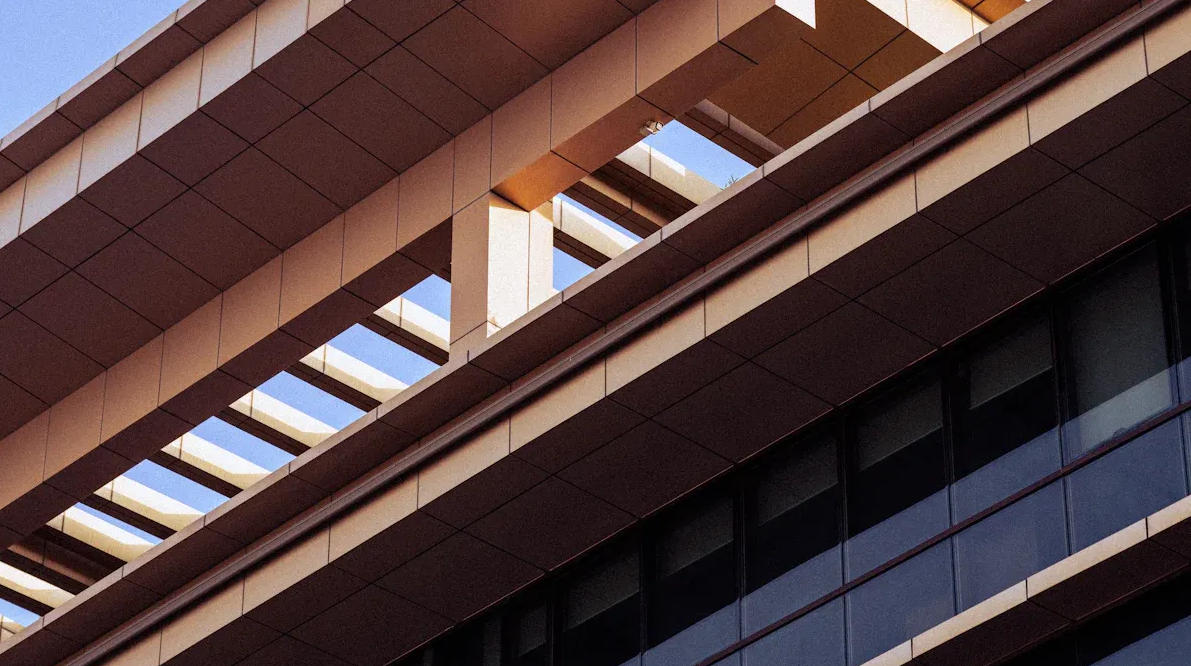

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є —Б–ї–µ–і—Г–µ—В —А–∞—Б—Б–Љ–∞—В—А–Є–≤–∞—В—М, –µ—Б–ї–Є –≤—Л —Е–Њ—В–Є—В–µ –і–Њ–±–Є—В—М—Б—П –±–∞–ї–∞–љ—Б–∞ –Љ–µ–ґ–і—Г –њ—А–Њ—З–љ–Њ—Б—В—М—О, –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М—О –Є –ї–µ–≥–Ї–Њ—Б—В—М—О –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є. –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ —Н–Ї—Б—В—А—Г–Ј–Є–Њ–љ–љ—Л–µ –њ—А–Њ—Д–Є–ї–Є —Е–Њ—А–Њ—И–Њ –њ–Њ–і—Е–Њ–і—П—В –і–ї—П —Д–∞—Б–∞–і–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤ –≤ –і–Њ–Љ–∞—Е, –Њ—Д–Є—Б–∞—Е –Є –Њ–±—Й–µ—Б—В–≤–µ–љ–љ—Л—Е –Ј–і–∞–љ–Є—П—Е.

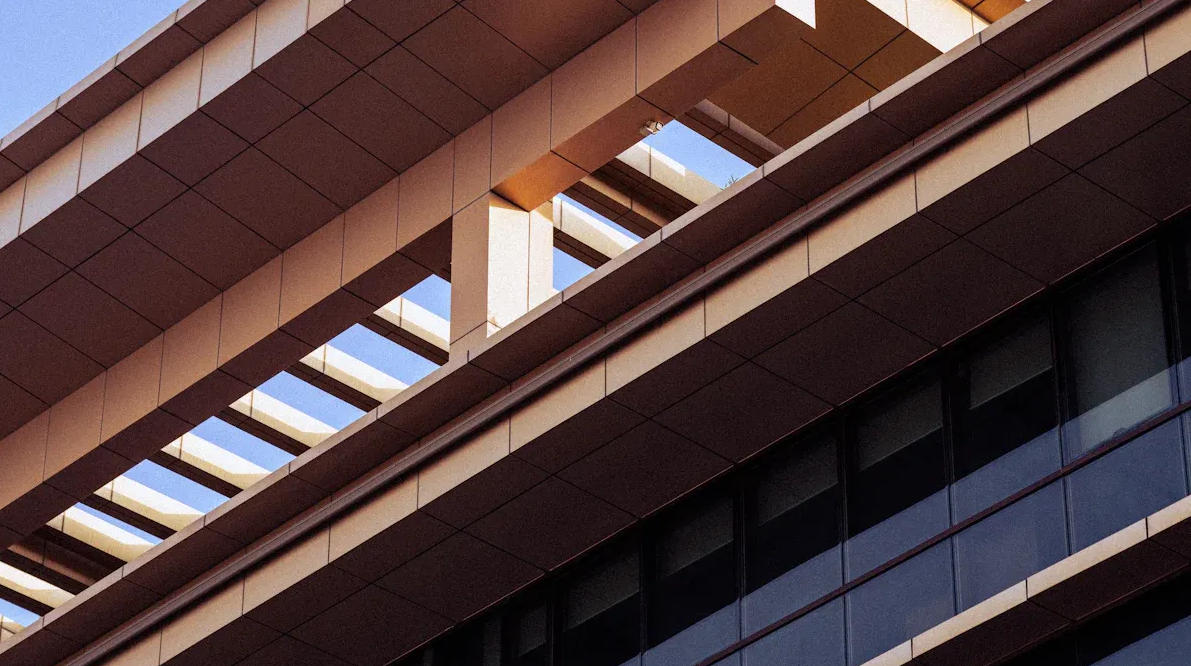

–∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –љ–∞–≤–µ—Б–љ—Л–µ —Д–∞—Б–∞–і–љ—Л–µ —Б–Є—Б—В–µ–Љ—Л

–Т –≤—Л—Б–Њ—В–љ—Л—Е –Ј–і–∞–љ–Є—П—Е –Њ–љ–Є –ї–µ–≥–Ї–Є–µ –Є –њ—А–Њ—З–љ—Л–µ. –Я—А–Њ–Љ—Л—И–ї–µ–љ–љ—Л–µ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –њ—А–µ–і–ї–∞–≥–∞—О—В –љ–∞–і–µ–ґ–љ—Л–µ —А–µ—И–µ–љ–Є—П –і–ї—П –Ї–∞—А–Ї–∞—Б–Њ–≤ –Љ–∞—И–Є–љ –Є –Њ–±–Њ—А—Г–і–Њ–≤–∞–љ–Є—П.

–Т–Њ—В –љ–µ—Б–Ї–Њ–ї—М–Ї–Њ —В–Є–њ–Є—З–љ—Л—Е –Њ–±–ї–∞—Б—В–µ–є –њ—А–Є–Љ–µ–љ–µ–љ–Є—П –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є, –њ–Њ–ї—Г—З–µ–љ–љ—Л—Е –Љ–µ—В–Њ–і–Њ–Љ —Н–Ї—Б—В—А—Г–Ј–Є–Є:

|

–Я—А–Є–ї–Њ–ґ–µ–љ–Є–µ

|

–Ю—Б–љ–Њ–≤–љ—Л–µ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞

|

–Ґ–Є–њ–Є—З–љ—Л–µ –њ—А–Є–Љ–µ—А—Л

|

|

–Ю–Ї–Њ–љ–љ—Л–µ –Є –і–≤–µ—А–љ—Л–µ —А–∞–Љ—Л

|

–Я—А–Њ—З–љ—Л–є, –љ–µ–њ—А–Є—Е–Њ—В–ї–Є–≤—Л–є –≤ —Г—Е–Њ–і–µ, —Б—В–Є–ї—М–љ—Л–є.

|

–Ц–Є–ї—Л–µ –Є –Њ—Д–Є—Б–љ—Л–µ –Ј–і–∞–љ–Є—П

|

|

–Э–∞–≤–µ—Б–љ—Л–µ —Б—В–µ–љ—Л

|

–Ы—С–≥–Ї–Є–є, –њ—А–Њ—З–љ—Л–є, —Е–Њ—А–Њ—И–Њ –≤—Л–≥–ї—П–і–Є—В.

|

–Т—Л—Б–Њ—В–љ—Л–µ –Њ—Д–Є—Б–љ—Л–µ –Ј–і–∞–љ–Є—П, –Њ–±—Й–µ—Б—В–≤–µ–љ–љ—Л–µ –Ј–і–∞–љ–Є—П

|

|

–Ъ—А–Њ–≤–µ–ї—М–љ—Л–µ –Є –Њ–±–ї–Є—Ж–Њ–≤–Њ—З–љ—Л–µ —А–∞–±–Њ—В—Л

|

–Э–µ—А–ґ–∞–≤–µ—О—Й–Є–є, –ї–µ–≥–Ї–Є–є

|

–Ч–∞–≤–Њ–і—Л, –љ–Њ–≤—Л–µ –і–Њ–Љ–∞

|

|

–°—В—А–Њ–Є—В–µ–ї—М–љ—Л–µ –ї–µ—Б–∞

|

–Я—А–Њ—З–љ—Л–є, –љ–Њ –љ–µ —В—П–ґ–µ–ї—Л–є

|

–°—В—А–Њ–Є—В–µ–ї—М–љ—Л–µ –њ–ї–Њ—Й–∞–і–Ї–Є

|

|

–Т–љ—Г—В—А–µ–љ–љ—П—П –Њ—В–і–µ–ї–Ї–∞

|

–Ы–µ–≥–Ї–Њ –њ—А–Њ–µ–Ї—В–Є—А—Г–µ—В—Б—П, –і–Њ–ї–≥–Њ–≤–µ—З–µ–љ.

|

–°—В–µ–љ—Л –Њ—Д–Є—Б–∞, –Њ—В–і–µ–ї–Ї–∞

|

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—В –њ–Њ–ї–љ—Г—О —Б–≤–Њ–±–Њ–і—Г —В–≤–Њ—А—З–µ—Б—В–≤–∞. –Т–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ–Њ–є –љ–∞—Б—В—А–Њ–є–Ї–Є –њ–Њ–Ј–≤–Њ–ї—П–µ—В —Б–Њ–Ј–і–∞–≤–∞—В—М –њ—А–Њ—Д–Є–ї–Є, –њ–Њ–і—Е–Њ–і—П—Й–Є–µ –і–ї—П —Г–љ–Є–Ї–∞–ї—М–љ—Л—Е —Д–∞—Б–∞–і–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤ –Є–ї–Є –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ—Л—Е –љ—Г–ґ–і. –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –ї–µ–≥–Ї–Њ —А–µ–Ј–∞—В—М –Є –њ—А–Є–і–∞–≤–∞—В—М –Є–Љ –љ—Г–ґ–љ—Г—О —Д–Њ—А–Љ—Г, –њ–Њ—Н—В–Њ–Љ—Г –Є—Е –Љ–Њ–ґ–љ–Њ –∞–і–∞–њ—В–Є—А–Њ–≤–∞—В—М –і–ї—П —Б–ї–Њ–ґ–љ—Л—Е –∞—А—Е–Є—В–µ–Ї—В—Г—А–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є –њ—А–Њ—Б–ї—Г–ґ–Є—В –і–Њ–ї—М—И–µ –і–µ—А–µ–≤–∞ –Є –±—Г–і–µ—В —Г—Б—В–Њ–є—З–Є–≤ –Ї –Ї–Њ—А—А–Њ–Ј–Є–Є, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАФ —А–∞–Ј—Г–Љ–љ—Л–є –≤—Л–±–Њ—А.

–Я—А–Є–Љ–µ—З–∞–љ–Є–µ: –Х—Б–ї–Є –≤–∞–Љ –љ–µ–Њ–±—Е–Њ–і–Є–Љ—Л –±—Л—Б—В—А—Л–µ —Б—А–Њ–Ї–Є –≤—Л–њ–Њ–ї–љ–µ–љ–Є—П –Ј–∞–Ї–∞–Ј–∞ –Є –љ–∞–і–µ–ґ–љ–Њ–µ –Ї–∞—З–µ—Б—В–≤–Њ, –Ї–Њ–Љ–њ–∞–љ–Є—П Guang Ya Aluminium Industries Co., Ltd. –Љ–Њ–ґ–µ—В –Є–Ј–≥–Њ—В–Њ–≤–Є—В—М –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –љ–∞ –Ј–∞–Ї–∞–Ј –і–ї—П –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞.

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞ —Н–Ї—Б—В—А—Г–Ј–Є–Њ–љ–љ–Њ–є –Њ–±—А–∞–±–Њ—В–Ї–Є –∞–ї—О–Љ–Є–љ–Є—П: –Њ–њ—В–Є–Љ–∞–ї—М–љ–Њ–µ —Б–Њ–Њ—В–љ–Њ—И–µ–љ–Є–µ –њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ–Њ—Б—В–Є –Є –≤–µ—Б–∞.

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞ –ї—С–≥–Ї–Њ–≥–Њ –≤–µ—Б–∞

–Т–∞–Љ –љ—Г–ґ–µ–љ —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л–є –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є —Г–њ—А–Њ—Б—В–Є—В —А–∞–±–Њ—В—Г –Є –Љ–Њ–љ—В–∞–ґ –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Р–ї—О–Љ–Є–љ–Є–є –і–∞–µ—В –≤–∞–Љ —Н—В–Њ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–Њ. –Х–≥–Њ –Љ–∞–ї—Л–є –≤–µ—Б –Њ–Ј–љ–∞—З–∞–µ—В, —З—В–Њ –≤—Л –Љ–Њ–ґ–µ—В–µ –њ–µ—А–µ–Љ–µ—Й–∞—В—М, –њ–Њ–і–љ–Є–Љ–∞—В—М –Є —Г—Б—В–∞–љ–∞–≤–ї–Є–≤–∞—В—М –њ—А–Њ—Д–Є–ї–Є —Б –Љ–µ–љ—М—И–Є–Љ–Є —Г—Б–Є–ї–Є—П–Љ–Є. –Т—Л —Н–Ї–Њ–љ–Њ–Љ–Є—В–µ –≤—А–µ–Љ—П –Є —Б–љ–Є–ґ–∞–µ—В–µ –Ј–∞—В—А–∞—В—Л –љ–∞ —А–∞–±–Њ—З—Г—О —Б–Є–ї—Г. –Х—Б–ї–Є —Б—А–∞–≤–љ–Є—В—М –∞–ї—О–Љ–Є–љ–Є–є —Б–Њ —Б—В–∞–ї—М—О –Є–ї–Є –і–µ—А–µ–≤–Њ–Љ, —А–∞–Ј–љ–Є—Ж–∞ –Њ—З–µ–≤–Є–і–љ–∞. –Р–ї—О–Љ–Є–љ–Є–є –≤–µ—Б–Є—В –љ–∞–Љ–љ–Њ–≥–Њ –Љ–µ–љ—М—И–µ, –њ–Њ—Н—В–Њ–Љ—Г –≤—Л –Љ–Њ–ґ–µ—В–µ –њ—А–Њ–µ–Ї—В–Є—А–Њ–≤–∞—В—М –±–Њ–ї–µ–µ –ї–µ–≥–Ї–Є–µ –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є –±–µ–Ј —Г—Й–µ—А–±–∞ –і–ї—П –њ—А–Њ—З–љ–Њ—Б—В–Є.

-

–°–Њ–Њ—В–љ–Њ—И–µ–љ–Є–µ –њ—А–Њ—З–љ–Њ—Б—В–Є –Є –≤–µ—Б–∞ вАФ –Њ–і–љ–∞ –Є–Ј –≥–ї–∞–≤–љ—Л—Е –њ—А–Є—З–Є–љ –њ–Њ–њ—Г–ї—П—А–љ–Њ—Б—В–Є –∞–ї—О–Љ–Є–љ–Є—П –≤ —Б—В—А–Њ–Є—В–µ–ї—М—Б—В–≤–µ.

-

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ —Б–њ–ї–∞–≤—Л –Њ–±–ї–∞–і–∞—О—В –≤–њ–µ—З–∞—В–ї—П—О—Й–µ–є –њ—А–Њ—З–љ–Њ—Б—В—М—О –њ—А–Є –Љ–µ–љ—М—И–µ–є –Љ–∞—Б—Б–µ, —З–µ–Љ —Б—В–∞–ї—М.

-

–Т —А–µ–Ј—Г–ї—М—В–∞—В–µ –≤—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –±–Њ–ї–µ–µ –ї–µ–≥–Ї–Є–µ, –љ–Њ –њ—А–Њ—З–љ—Л–µ –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є, –∞ –Ј–љ–∞—З–Є—В, —В—А–∞—В–Є—В–µ –Љ–µ–љ—М—И–µ –љ–∞ —Д—Г–љ–і–∞–Љ–µ–љ—В –Є –Љ–∞—В–µ—А–Є–∞–ї—Л.

-

–£—Б—В–∞–љ–Њ–≤–Ї–∞ –њ—А–Њ—Е–Њ–і–Є—В –±—Л—Б—В—А–µ–µ, –њ–Њ—В–Њ–Љ—Г —З—В–Њ –љ–µ –љ—Г–ґ–љ–Њ –Є–Љ–µ—В—М –і–µ–ї–Њ —Б —В—П–ґ–µ–ї—Л–Љ–Є –Ї–Њ–Љ–њ–Њ–љ–µ–љ—В–∞–Љ–Є.

–Х—Б–ї–Є –≤—Л —А–∞–±–Њ—В–∞–µ—В–µ –љ–∞–і –њ—А–Њ–µ–Ї—В–∞–Љ–Є, –≥–і–µ –≤–∞–ґ–µ–љ –≤–µ—Б вАФ –љ–∞–њ—А–Є–Љ–µ—А, –≤—Л—Б–Њ—В–љ—Л–µ –Ј–і–∞–љ–Є—П, –Љ–Њ—Б—В—Л –Є–ї–Є –Љ–Њ–і—Г–ї—М–љ—Л–µ –і–Њ–Љ–∞ вАФ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –њ–Њ–Љ–Њ–≥—Г—В –≤–∞–Љ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Њ–≤–∞—В—М —Б—В—А–Њ–≥–Є–Љ —В—А–µ–±–Њ–≤–∞–љ–Є—П–Љ. –Р–ї—О–Љ–Є–љ–Є–є —В–∞–Ї–ґ–µ –Љ–Њ–ґ–љ–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞—В—М –≤ —В—А–∞–љ—Б–њ–Њ—А—В–љ–Њ–є –Є –∞—Н—А–Њ–Ї–Њ—Б–Љ–Є—З–µ—Б–Ї–Њ–є –Њ—В—А–∞—Б–ї—П—Е, –≥–і–µ –Ї–∞–ґ–і—Л–є –Ї–Є–ї–Њ–≥—А–∞–Љ–Љ –Є–Љ–µ–µ—В –Ј–љ–∞—З–µ–љ–Є–µ.

–°–Њ–≤–µ—В: –Ш—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є–µ –±–Њ–ї–µ–µ –ї–µ–≥–Ї–Є—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤ —Г–њ—А–Њ—Й–∞–µ—В —В—А–∞–љ—Б–њ–Њ—А—В–Є—А–Њ–≤–Ї—Г –Є –њ–Њ–≥—А—Г–Ј–Ї—Г. –≠—В–Њ –њ–Њ–Ј–≤–Њ–ї—П–µ—В —Б–Њ–Ї—А–∞—В–Є—В—М —В—А–∞–љ—Б–њ–Њ—А—В–љ—Л–µ —А–∞—Б—Е–Њ–і—Л –Є —Г—Б–Ї–Њ—А–Є—В—М —Б—А–Њ–Ї–Є –≤—Л–њ–Њ–ї–љ–µ–љ–Є—П –њ—А–Њ–µ–Ї—В–∞.

–°—В—А—Г–Ї—В—Г—А–љ—Л–µ —Е–∞—А–∞–Ї—В–µ—А–Є—Б—В–Є–Ї–Є

–Р–ї—О–Љ–Є–љ–Є–є –љ–µ —В–Њ–ї—М–Ї–Њ —Б–љ–Є–ґ–∞–µ—В –≤–µ—Б, –љ–Њ –Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –љ–∞–і–µ–ґ–љ—Г—О —А–∞–±–Њ—В—Г. –Т—Л—Б–Њ–Ї–Њ–µ —Б–Њ–Њ—В–љ–Њ—И–µ–љ–Є–µ –њ—А–Њ—З–љ–Њ—Б—В–Є –Ї –≤–µ—Б—Г –Њ–Ј–љ–∞—З–∞–µ—В, —З—В–Њ –∞–ї—О–Љ–Є–љ–Є–є –Љ–Њ–ґ–µ—В –≤—Л–і–µ—А–ґ–Є–≤–∞—В—М –±–Њ–ї—М—И–Є–µ –љ–∞–≥—А—Г–Ј–Ї–Є –±–µ–Ј —Г–≤–µ–ї–Є—З–µ–љ–Є—П –≥–∞–±–∞—А–Є—В–Њ–≤. –Э–∞–њ—А–Є–Љ–µ—А, —Б–њ–ї–∞–≤ 6061-T6 –Є–Љ–µ–µ—В –њ—А–µ–і–µ–ї –њ—А–Њ—З–љ–Њ—Б—В–Є –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ –Њ–Ї–Њ–ї–Њ 35 000 PSI. –≠—В–Њ–≥–Њ –і–Њ—Б—В–∞—В–Њ—З–љ–Њ –і–ї—П –Љ–љ–Њ–≥–Є—Е —Б–ї–Њ–ґ–љ—Л—Е –њ—А–Є–Љ–µ–љ–µ–љ–Є–є.

–Т—Л –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М —А–∞–Ј–ї–Є—З–љ—Л–µ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ —Б–њ–ї–∞–≤—Л –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ–Є –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Э–µ–Ї–Њ—В–Њ—А—Л–µ —Б–њ–ї–∞–≤—Л, –љ–∞–њ—А–Є–Љ–µ—А 7075, –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—В –љ–µ–њ—А–µ–≤–Ј–Њ–є–і–µ–љ–љ—Г—О –њ—А–Њ—З–љ–Њ—Б—В—М –і–ї—П –≤—Л—Б–Њ–Ї–Њ–њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ—Л—Е –њ—А–Є–Љ–µ–љ–µ–љ–Є–є. –Ф—А—Г–≥–Є–µ, –љ–∞–њ—А–Є–Љ–µ—А 6063, –њ–Њ–Ј–≤–Њ–ї—П—О—В –њ–Њ–ї—Г—З–Є—В—М –њ—А–µ–≤–Њ—Б—Е–Њ–і–љ—Г—О –Њ—В–і–µ–ї–Ї—Г –і–ї—П –∞—А—Е–Є—В–µ–Ї—В—Г—А–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤. –Т—Л –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М –њ–Њ–і—Е–Њ–і—П—Й–Є–є —Б–њ–ї–∞–≤ –≤ –Ј–∞–≤–Є—Б–Є–Љ–Њ—Б—В–Є –Њ—В –љ–µ—Б—Г—Й–µ–є —Б–њ–Њ—Б–Њ–±–љ–Њ—Б—В–Є, —Н—Б—В–µ—В–Є—З–µ—Б–Ї–Є—Е –Ї–∞—З–µ—Б—В–≤ –Є–ї–Є —В—А–µ–±–Њ–≤–∞–љ–Є–є –Ї –Є–Ј–≥–Њ—В–Њ–≤–ї–µ–љ–Є—О.

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є —В–∞–Ї–ґ–µ —Г—Б—В–Њ–є—З–Є–≤—Л –Ї –Ї–Њ—А—А–Њ–Ј–Є–Є, –Њ—Б–Њ–±–µ–љ–љ–Њ –њ—А–Є –њ—А–∞–≤–Є–ї—М–љ–Њ–є –Њ–±—А–∞–±–Њ—В–Ї–µ –њ–Њ–≤–µ—А—Е–љ–Њ—Б—В–Є. –Ш—Е –Љ–Њ–ґ–љ–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞—В—М –≤ –Љ–Њ—А—Б–Ї–Њ–є —Б—А–µ–і–µ, —Б–Є—Б—В–µ–Љ–∞—Е –≤–Њ–Ј–Њ–±–љ–Њ–≤–ї—П–µ–Љ–Њ–є —Н–љ–µ—А–≥–Є–Є –Є —Н–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —З–Є—Б—В—Л—Е –Ј–і–∞–љ–Є—П—Е. –Т–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є –і–µ–ї–∞–µ—В –∞–ї—О–Љ–Є–љ–Є–є —В–∞–Ї–ґ–µ —Н–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —Г—Б—В–Њ–є—З–Є–≤—Л–Љ –≤—Л–±–Њ—А–Њ–Љ.

-

–Э–µ—Б—Г—Й–∞—П —Б–њ–Њ—Б–Њ–±–љ–Њ—Б—В—М –Є–Љ–µ–µ—В —А–µ—И–∞—О—Й–µ–µ –Ј–љ–∞—З–µ–љ–Є–µ –≤ —Б—В—А–Њ–Є—В–µ–ї—М—Б—В–≤–µ –Є –∞–≤—В–Њ–Љ–Њ–±–Є–ї–µ—Б—В—А–Њ–µ–љ–Є–Є.

-

–Э–µ–Ї–Њ—В–Њ—А—Л–µ —Б–њ–ї–∞–≤—Л –ї–µ–≥—З–µ –њ–Њ–і–і–∞—О—В—Б—П –Љ–µ—Е–∞–љ–Є—З–µ—Б–Ї–Њ–є –Њ–±—А–∞–±–Њ—В–Ї–µ –Є–ї–Є —Б–≤–∞—А–Ї–µ, —З—В–Њ –Њ–±–ї–µ–≥—З–∞–µ—В –Є–Ј–≥–Њ—В–Њ–≤–ї–µ–љ–Є–µ –Є–Ј–і–µ–ї–Є–є.

-

–Р–ї—О–Љ–Є–љ–Є–є —Е–Њ—А–Њ—И–Њ –њ–Њ–і–і–∞–µ—В—Б—П –њ–µ—А–µ—А–∞–±–Њ—В–Ї–µ, –њ–Њ—Н—В–Њ–Љ—Г –≤—Л –њ–Њ–і–і–µ—А–ґ–Є–≤–∞–µ—В–µ —Н–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —З–Є—Б—В—Л–µ –Љ–µ—В–Њ–і—Л –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–∞.

–Т —З–µ–Љ –∞–ї—О–Љ–Є–љ–Є–є –њ—А–µ–≤–Њ—Б—Е–Њ–і–Є—В –∞–ї—М—В–µ—А–љ–∞—В–Є–≤—Л

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ, –≤—Л –Ј–∞–і–∞–µ—В–µ—Б—М –≤–Њ–њ—А–Њ—Б–Њ–Љ, –≤ —З–µ–Љ –∞–ї—О–Љ–Є–љ–Є–є –њ—А–µ–≤–Њ—Б—Е–Њ–і–Є—В —В–∞–Ї–Є–µ –∞–ї—М—В–µ—А–љ–∞—В–Є–≤—Л, –Ї–∞–Ї —Б—В–∞–ї—М, –і–µ—А–µ–≤–Њ –Є–ї–Є –њ–ї–∞—Б—В–Є–Ї. –Ю—В–≤–µ—В –Ј–∞–≤–Є—Б–Є—В –Њ—В —Ж–µ–ї–µ–є –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Р–ї—О–Љ–Є–љ–Є–є –њ—А–Њ—П–≤–ї—П–µ—В —Б–µ–±—П –љ–∞–Є–ї—Г—З—И–Є–Љ –Њ–±—А–∞–Ј–Њ–Љ –≤ –Њ—В—А–∞—Б–ї—П—Е –Є —Б—Ж–µ–љ–∞—А–Є—П—Е, –≥–і–µ –≤–µ—Б, –њ—А–Њ—З–љ–Њ—Б—В—М –Є –њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ–Њ—Б—В—М –Є–Љ–µ—О—В –њ–µ—А–≤–Њ—Б—В–µ–њ–µ–љ–љ–Њ–µ –Ј–љ–∞—З–µ–љ–Є–µ.

|

–Ю—В—А–∞—Б–ї—М/–°—Ж–µ–љ–∞—А–Є–є

|

–Я—А–Є–Љ–µ–љ–µ–љ–Є–µ/–°—Ж–µ–љ–∞—А–Є–є –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П

|

–Я—А–Є—З–Є–љ–∞ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П –∞–ї—О–Љ–Є–љ–Є—П

|

|

–Т–Њ–Ј–Њ–±–љ–Њ–≤–ї—П–µ–Љ–∞—П —Н–љ–µ—А–≥–Є—П

|

–†–∞–Љ–Ї–Є –і–ї—П —Б–Њ–ї–љ–µ—З–љ—Л—Е –њ–∞–љ–µ–ї–µ–є

|

–Ы–µ–≥–Ї–Є–є, –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ—Б—В–Њ–є–Ї–Є–є, –љ–µ –і–Њ–±–∞–≤–ї—П–µ—В –ї–Є—И–љ–µ–≥–Њ –≤–µ—Б–∞ —Д–Њ—В–Њ—Н–ї–µ–Ї—В—А–Є—З–µ—Б–Ї–Є–Љ —Б–Є—Б—В–µ–Љ–∞–Љ.

|

|

|

–°–Є—Б—В–µ–Љ—Л –Ї—А–µ–њ–ї–µ–љ–Є—П (—Б—В–µ–ї–ї–∞–ґ–Є –Є –љ–∞–њ—А–∞–≤–ї—П—О—Й–Є–µ)

|

–Э–∞–і–µ–ґ–љ—Л–µ, –∞–і–∞–њ—В–Є—А—Г–µ–Љ—Л–µ –њ–ї–∞—В—Д–Њ—А–Љ—Л, –Ї–Њ—В–Њ—А—Л–µ –Љ–Њ–ґ–љ–Њ –љ–∞—Б—В—А–∞–Є–≤–∞—В—М –њ–Њ–і —А–∞–Ј–ї–Є—З–љ—Л–µ —Б–Є—Б—В–µ–Љ—Л.

|

|

|

–†–∞–і–Є–∞—В–Њ—А—Л –Є —В–µ–њ–ї–Њ–Њ—В–≤–Њ–і—Л

|

–Т—Л—Б–Њ–Ї–∞—П —В–µ–њ–ї–Њ–њ—А–Њ–≤–Њ–і–љ–Њ—Б—В—М –њ–Њ–Љ–Њ–≥–∞–µ—В —А–µ–≥—Г–ї–Є—А–Њ–≤–∞—В—М —В–µ–Љ–њ–µ—А–∞—В—Г—А—Г –і–ї—П –Њ–њ—В–Є–Љ–∞–ї—М–љ–Њ–є —А–∞–±–Њ—В—Л —Б–Њ–ї–љ–µ—З–љ—Л—Е –њ–∞–љ–µ–ї–µ–є.

|

|

|

–Ъ–Њ—А–њ—Г—Б–∞ –Є —А–∞—Б–њ—А–µ–і–µ–ї–Є—В–µ–ї—М–љ—Л–µ –Ї–Њ—А–Њ–±–Ї–Є

|

–Ч–∞—Й–Є—Й–∞–µ—В –Ї–Њ–Љ–њ–Њ–љ–µ–љ—В—Л –Њ—В –≤–Њ–Ј–і–µ–є—Б—В–≤–Є—П –Њ–Ї—А—Г–ґ–∞—О—Й–µ–є —Б—А–µ–і—Л –Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В —Н—Д—Д–µ–Ї—В–Є–≤–љ–Њ–µ —А–∞—Б—Б–µ–Є–≤–∞–љ–Є–µ —В–µ–њ–ї–∞.

|

|

–Т–µ—В—А–Њ—Н–љ–µ—А–≥–µ—В–Є–Ї–∞

|

–Ь–Њ—А—Б–Ї–Є–µ –≤–µ—В—А–Њ—В—Г—А–±–Є–љ—Л

|

–Ю–±–ї–∞–і–∞–µ—В –њ—А–µ–≤–Њ—Б—Е–Њ–і–љ–Њ–є –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ–є —Б—В–Њ–є–Ї–Њ—Б—В—М—О –≤ –Љ–Њ—А—Б–Ї–Њ–є —Б—А–µ–і–µ, –∞ —В–∞–Ї–ґ–µ –Љ–∞–ї—Л–Љ –≤–µ—Б–Њ–Љ –њ–Њ —Б—А–∞–≤–љ–µ–љ–Є—О —Б –і—А—Г–≥–Є–Љ–Є –Љ–µ—В–∞–ї–ї–∞–Љ–Є.

|

|

–У–Є–і—А–Њ—Н–љ–µ—А–≥–µ—В–Є–Ї–∞

|

–†–∞–Ј–ї–Є—З–љ—Л–µ –Ї–Њ–Љ–њ–Њ–љ–µ–љ—В—Л (–Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є –≤–Њ–і–Њ–≤–Њ–і–Њ–≤, –Ј–∞—В–≤–Њ—А—Л, –Ї–ї–∞–њ–∞–љ—Л –Є —В. –і.)

|

–°–љ–Є–ґ–∞–µ—В –Ј–∞—В—А–∞—В—Л –Є –њ—А–µ–і–Њ—В–≤—А–∞—Й–∞–µ—В –Ї–Њ—А—А–Њ–Ј–Є—О, –њ–Њ–і—Е–Њ–і–Є—В –і–ї—П –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П –≤ —Г—Б–ї–Њ–≤–Є—П—Е –≤–Њ–Ј–і–µ–є—Б—В–≤–Є—П –≤–Њ–і—Л.

|

|

¬Ђ–Ч–µ–ї–µ–љ—Л–µ –Ј–і–∞–љ–Є—П¬ї

|

–≠–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —З–Є—Б—В—Л–µ —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л–µ –Љ–∞—В–µ—А–Є–∞–ї—Л

|

–Ы–µ–≥–Ї–Є–є, –њ—А–Њ—З–љ—Л–є, –њ–Њ–і–∞—В–ї–Є–≤—Л–є –Є –њ—А–Є–≥–Њ–і–љ—Л–є –і–ї—П –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є, —Б–Њ–Њ—В–≤–µ—В—Б—В–≤—Г—О—Й–Є–є –њ—А–Є–љ—Ж–Є–њ–∞–Љ —Г—Б—В–Њ–є—З–Є–≤–Њ–≥–Њ –і–Є–Ј–∞–є–љ–∞.

|

–Т—Л –≤–Є–і–Є—В–µ, –Ї–∞–Ї –∞–ї—О–Љ–Є–љ–Є–є –њ—А–µ–≤–Њ—Б—Е–Њ–і–Є—В —Б—В–∞–ї—М, –і–µ—А–µ–≤–Њ –Є –њ–ї–∞—Б—В–Є–Ї –≤ –≤–Њ–Ј–Њ–±–љ–Њ–≤–ї—П–µ–Љ–Њ–є —Н–љ–µ—А–≥–µ—В–Є–Ї–µ, –≤–µ—В—А–Њ—Н–љ–µ—А–≥–µ—В–Є–Ї–µ –Є –≥–Є–і—А–Њ—Н–љ–µ—А–≥–µ—В–Є–Ї–µ. –Р–ї—О–Љ–Є–љ–Є–µ–≤–∞—П –њ—А–Њ–≤–Њ–і–Ї–∞ –≤–µ—Б–Є—В –њ—А–Є–Љ–µ—А–љ–Њ –љ–∞ 70% –Љ–µ–љ—М—И–µ –Љ–µ–і–љ–Њ–є, —З—В–Њ —Г–њ—А–Њ—Й–∞–µ—В –Љ–Њ–љ—В–∞–ґ –Є —Б–љ–Є–ґ–∞–µ—В –Ј–∞—В—А–∞—В—Л. –Т —Н–Ї–Њ–ї–Њ–≥–Є—З–µ—Б–Ї–Є —З–Є—Б—В—Л—Е –Ј–і–∞–љ–Є—П—Е –ї–µ–≥–Ї–Њ—Б—В—М –Є –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є –∞–ї—О–Љ–Є–љ–Є—П —Б–њ–Њ—Б–Њ–±—Б—В–≤—Г—О—В —Г—Б—В–Њ–є—З–Є–≤–Њ–Љ—Г –њ—А–Њ–µ–Ї—В–Є—А–Њ–≤–∞–љ–Є—О.

–Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, —Б–Њ—З–µ—В–∞—О—Й–Є–є –≤ —Б–µ–±–µ –њ—А–Њ—З–љ–Њ—Б—В—М, —Н–Ї—Б–њ–ї—Г–∞—В–∞—Ж–Є–Њ–љ–љ—Л–µ —Е–∞—А–∞–Ї—В–µ—А–Є—Б—В–Є–Ї–Є –Є —Б–љ–Є–ґ–µ–љ–Є–µ –≤–µ—Б–∞,

–∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є

–≠—В–Њ —А–∞–Ј—Г–Љ–љ—Л–є –≤—Л–±–Њ—А. –Т—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–Њ –≤ —Б–Њ–Њ—В–љ–Њ—И–µ–љ–Є–Є –њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ–Њ—Б—В–Є –Є –≤–µ—Б–∞ –≤ –ї—О–±–Њ–Љ –њ—А–Є–Љ–µ–љ–µ–љ–Є–Є, –Њ—В –Ї–∞—А–Ї–∞—Б–Њ–≤ —Б–Њ–ї–љ–µ—З–љ—Л—Е –њ–∞–љ–µ–ї–µ–є –і–Њ –Љ–Њ—А—Б–Ї–Є—Е –≤–µ—В—А–Њ—В—Г—А–±–Є–љ. –Р–ї—О–Љ–Є–љ–Є–є –њ–Њ–Љ–Њ–≥–∞–µ—В —Б–Њ–Ј–і–∞–≤–∞—В—М –±–Њ–ї–µ–µ –ї–µ–≥–Ї–Є–µ, –њ—А–Њ—З–љ—Л–µ –Є —Н—Д—Д–µ–Ї—В–Є–≤–љ—Л–µ –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є.

–Я—А–Є–Љ–µ—З–∞–љ–Є–µ: –Т—Л–±–Є—А–∞—П –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є, –≤—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –≥–Є–±–Ї–Њ—Б—В—М, –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є —П–≤–љ–Њ–µ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–Њ –≤ —Б–Њ–Њ—В–љ–Њ—И–µ–љ–Є–Є –њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ–Њ—Б—В–Є –Є –≤–µ—Б–∞ –њ–Њ —Б—А–∞–≤–љ–µ–љ–Є—О —Б –±–Њ–ї–µ–µ —В—П–ґ–µ–ї—Л–Љ–Є –Љ–∞—В–µ—А–Є–∞–ї–∞–Љ–Є.

–°—В–∞–ї—М –њ—А–Њ—В–Є–≤ –∞–ї—О–Љ–Є–љ–Є—П

–Я—А–Њ—З–љ–Њ—Б—В—М —Б—В–∞–ї–Є

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ, –≤—Л –Ј–∞–і–∞–µ—В–µ—Б—М –≤–Њ–њ—А–Њ—Б–Њ–Љ, –њ–Њ—З–µ–Љ—Г —Б—В–∞–ї—М –і–Њ —Б–Є—Е –њ–Њ—А –≤—Л–±–Є—А–∞—О—В –і–ї—П —Б—В–Њ–ї—М–Ї–Є—Е –Ї—А—Г–њ–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤. –°—В–∞–ї—М –≤—Л–і–µ–ї—П–µ—В—Б—П —Б–≤–Њ–µ–є –≤–њ–µ—З–∞—В–ї—П—О—Й–µ–є –њ—А–Њ—З–љ–Њ—Б—В—М—О –Є –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М—О. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, —Б–њ–Њ—Б–Њ–±–љ—Л–є –≤—Л–і–µ—А–ґ–Є–≤–∞—В—М –±–Њ–ї—М—И–Є–µ –љ–∞–≥—А—Г–Ј–Ї–Є –Є –≤—Л—Б–Њ–Ї–Є–µ –љ–∞–њ—А—П–ґ–µ–љ–Є—П, —Б—В–∞–ї—М вАФ –ї—Г—З—И–Є–є –≤—Л–±–Њ—А. –Ю–љ–∞ –Њ–±–ї–∞–і–∞–µ—В –±–Њ–ї–µ–µ –≤—Л—Б–Њ–Ї–Є–Љ –њ—А–µ–і–µ–ї–Њ–Љ —В–µ–Ї—Г—З–µ—Б—В–Є –Є –њ—А–µ–і–µ–ї–Њ–Љ –њ—А–Њ—З–љ–Њ—Б—В–Є –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ –њ–Њ —Б—А–∞–≤–љ–µ–љ–Є—О —Б –∞–ї—О–Љ–Є–љ–Є–µ–Љ, —З—В–Њ –Њ–Ј–љ–∞—З–∞–µ—В, —З—В–Њ –Њ–љ–∞ –Љ–Њ–ґ–µ—В –≤—Л–і–µ—А–ґ–Є–≤–∞—В—М –±–Њ–ї—М—И–Є–є –≤–µ—Б –±–µ–Ј –Є–Ј–≥–Є–±–∞ –Є–ї–Є –њ–Њ–ї–Њ–Љ–Ї–Є. –Т–Ј–≥–ї—П–љ–Є—В–µ –љ–∞ —Н—В–Њ –Ї—А–∞—В–Ї–Њ–µ —Б—А–∞–≤–љ–µ–љ–Є–µ:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–Я—А–µ–і–µ–ї —В–µ–Ї—Г—З–µ—Б—В–Є (–Ь–Я–∞)

|

–Я—А–µ–і–µ–ї –њ—А–Њ—З–љ–Њ—Б—В–Є –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ (–Ь–Я–∞)

|

|

–°—В–∞–ї—М

|

~250

|

400-500

|

|

–Р–ї—О–Љ–Є–љ–Є–є (6061)

|

~40

|

~90

|

–Ъ—А–Њ–Љ–µ —В–Њ–≥–Њ, –і–ї—П –і–Њ—Б—В–Є–ґ–µ–љ–Є—П —В–Њ–є –ґ–µ –њ—А–Њ—З–љ–Њ—Б—В–Є, —З—В–Њ –Є —Г –∞–ї—О–Љ–Є–љ–Є—П, —Б—В–∞–ї—М —В—А–µ–±—Г–µ—В –Љ–µ–љ—М—И–µ–є —В–Њ–ї—Й–Є–љ—Л –Љ–∞—В–µ—А–Є–∞–ї–∞. –Ш–Љ–µ–љ–љ–Њ –њ–Њ—Н—В–Њ–Љ—Г —Б—В–∞–ї—М –Є—Б–њ–Њ–ї—М–Ј—Г–µ—В—Б—П –≤ –Ї–∞—А–Ї–∞—Б–∞—Е –љ–µ–±–Њ—Б–Ї—А–µ–±–Њ–≤, –Љ–Њ—Б—В–Њ–≤ –Є –і—А—Г–≥–Є—Е –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є—П—Е, –≥–і–µ –±–µ–Ј–Њ–њ–∞—Б–љ–Њ—Б—В—М –Є —Г—Б—В–Њ–є—З–Є–≤–Њ—Б—В—М –Є–Љ–µ—О—В –њ–µ—А–≤–Њ—Б—В–µ–њ–µ–љ–љ–Њ–µ –Ј–љ–∞—З–µ–љ–Є–µ. –Ю–љ–∞ –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –±–Њ–ї—М—И—Г—О –њ—А–Њ—З–љ–Њ—Б—В—М –љ–∞ —Б–і–≤–Є–≥, —З—В–Њ –њ–Њ–Љ–Њ–≥–∞–µ—В –њ—А–µ–і–Њ—В–≤—А–∞—В–Є—В—М –Њ–±—А–∞–Ј–Њ–≤–∞–љ–Є–µ —В—А–µ—Й–Є–љ –Є –і–µ—Д–Њ—А–Љ–∞—Ж–Є—О —Б —В–µ—З–µ–љ–Є–µ–Љ –≤—А–µ–Љ–µ–љ–Є.

-

–°—В–∞–ї—М –њ—А–µ–і–њ–Њ—З—В–Є—В–µ–ї—М–љ–µ–µ –і–ї—П –љ–µ—Б—Г—Й–Є—Е –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–є –Є –Ї–∞—А–Ї–∞—Б–Њ–≤ –њ–Њ–≤—Л—И–µ–љ–љ–Њ–є –њ—А–Њ—З–љ–Њ—Б—В–Є.

-

–Ю–љ –±–Њ–ї–µ–µ –і–Њ–ї–≥–Њ–≤–µ—З–µ–љ, —З—В–Њ –і–µ–ї–∞–µ—В –µ–≥–Њ –љ–∞–і–µ–ґ–љ—Л–Љ –≤—Л–±–Њ—А–Њ–Љ –і–ї—П –і–ї–Є—В–µ–ї—М–љ–Њ–≥–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П.

–°–ї–∞–±—Л–µ —Б—В–Њ—А–Њ–љ—Л —Б—В–∞–ї–Є

–°—В–∞–ї—М –љ–µ –Є–і–µ–∞–ї—М–љ–∞ –і–ї—П –ї—О–±–Њ–є —А–∞–±–Њ—В—Л. –Т—Л –Ј–∞–Љ–µ—В–Є—В–µ, —З—В–Њ —Б—В–∞–ї—М –≤–µ—Б–Є—В –љ–∞–Љ–љ–Њ–≥–Њ –±–Њ–ї—М—И–µ –∞–ї—О–Љ–Є–љ–Є—П, —З—В–Њ –Љ–Њ–ґ–µ—В —Г—Б–ї–Њ–ґ–љ–Є—В—М –µ—С —В—А–∞–љ—Б–њ–Њ—А—В–Є—А–Њ–≤–Ї—Г –Є –Љ–Њ–љ—В–∞–ґ. –Ю–љ–∞ —В–∞–Ї–ґ–µ –±–Њ–ї–µ–µ –њ–Њ–і–≤–µ—А–ґ–µ–љ–∞ –Ї–Њ—А—А–Њ–Ј–Є–Є, –Њ—Б–Њ–±–µ–љ–љ–Њ –≤ —Б—Г—А–Њ–≤—Л—Е —Г—Б–ї–Њ–≤–Є—П—Е, –њ–Њ—Н—В–Њ–Љ—Г —З–∞—Б—В–Њ —В—А–µ–±—Г–µ—В—Б—П –і–Њ–њ–Њ–ї–љ–Є—В–µ–ї—М–љ–Њ–µ –њ–Њ–Ї—А—Л—В–Є–µ –Є–ї–Є —А–µ–≥—Г–ї—П—А–љ–Њ–µ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ. –°–Њ –≤—А–µ–Љ–µ–љ–µ–Љ —Н—В–Є –Ј–∞—В—А–∞—В—Л –љ–∞ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –љ–∞–Ї–∞–њ–ї–Є–≤–∞—О—В—Б—П.

–Т–Њ—В –Ї—А–∞—В–Ї–Є–є –Њ–±–Ј–Њ—А —А–∞–Ј–ї–Є—З–Є–є –≤ —Б—В–Њ–Є–Љ–Њ—Б—В–Є:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–°—В–Њ–Є–Љ–Њ—Б—В—М –Ј–∞ —Д—Г–љ—В

|

–Я—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–µ–љ–љ—Л–є –њ—А–Њ—Ж–µ—Б—Б

|

–°—В–Њ–Є–Љ–Њ—Б—В—М –ґ–Є–Ј–љ–µ–љ–љ–Њ–≥–Њ —Ж–Є–Ї–ї–∞

|

–Ч–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

1,00вАУ1,50 –і–Њ–ї–ї. –°–®–Р

|

–≠–љ–µ—А–≥–Њ–µ–Љ–Ї–Є–є

|

–С–Њ–ї–µ–µ –љ–Є–Ј–Ї–Є–є —Г—А–Њ–≤–µ–љ—М –Є–Ј-–Ј–∞ –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ–є —Б—В–Њ–є–Ї–Њ—Б—В–Є.

|

–Т –∞–≥—А–µ—Б—Б–Є–≤–љ—Л—Е —Б—А–µ–і–∞—Е —Б–љ–Є–ґ–∞–µ—В—Б—П.

|

|

–°—В–∞–ї—М

|

0,30вАУ0,60 –і–Њ–ї–ї. –°–®–Р

|

–Ь–µ–љ–µ–µ —Н–љ–µ—А–≥–Њ–µ–Љ–Ї–Є–є

|

–С–Њ–ї–µ–µ –≤—Л—Б–Њ–Ї–∞—П —Ж–µ–љ–∞ –Њ–±—Г—Б–ї–Њ–≤–ї–µ–љ–∞ –љ–µ–Њ–±—Е–Њ–і–Є–Љ–Њ—Б—В—М—О —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–≥–Њ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є—П.

|

–Я–Њ–≤—Л—И–µ–љ–∞ –≤ –∞–≥—А–µ—Б—Б–Є–≤–љ—Л—Е —Б—А–µ–і–∞—Е.

|

–С–Њ–ї–µ–µ –љ–Є–Ј–Ї–∞—П –њ–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ–∞—П —Б—В–Њ–Є–Љ–Њ—Б—В—М —Б—В–∞–ї–Є –Њ–±—Г—Б–ї–Њ–≤–ї–µ–љ–∞ –Њ–±–Є–ї–Є–µ–Љ –ґ–µ–ї–µ–Ј–љ–Њ–є —А—Г–і—Л, –љ–Њ –≤ —В–µ—З–µ–љ–Є–µ –≤—Б–µ–≥–Њ —Б—А–Њ–Ї–∞ —Н–Ї—Б–њ–ї—Г–∞—В–∞—Ж–Є–Є –њ—А–Њ–µ–Ї—В–∞ –Ј–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –Љ–Њ–≥—Г—В –±—Л—В—М –≤—Л—И–µ. –Т–Њ–Ј–і–µ–є—Б—В–≤–Є–µ –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г вАФ –µ—Й–µ –Њ–і–Є–љ —Д–∞–Ї—В–Њ—А. –Я—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–Њ —Б—В–∞–ї–Є –Є –∞–ї—О–Љ–Є–љ–Є—П –њ–Њ—В—А–µ–±–ї—П–µ—В –Љ–љ–Њ–≥–Њ —Н–љ–µ—А–≥–Є–Є, –љ–Њ –љ–Њ–≤—Л–µ –Љ–µ—В–Њ–і—Л —Б –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є–µ–Љ –њ–µ—А–µ—А–∞–±–Њ—В–∞–љ–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤ –Є –≤–Њ–Ј–Њ–±–љ–Њ–≤–ї—П–µ–Љ—Л—Е –Є—Б—В–Њ—З–љ–Є–Ї–Њ–≤ —Н–љ–µ—А–≥–Є–Є –њ–Њ–Љ–Њ–≥–∞—О—В —Б–Њ–Ї—А–∞—В–Є—В—М –≤—Л–±—А–Њ—Б—Л.

–Т—Л–±–Њ—А —Б—В–∞–ї–Є –Є–ї–Є –∞–ї—О–Љ–Є–љ–Є—П

–Ш—В–∞–Ї, –Ї–∞–Ї–Њ–є –Љ–∞—В–µ—А–Є–∞–ї –ї—Г—З—И–µ –≤—Б–µ–≥–Њ –њ–Њ–і—Е–Њ–і–Є—В –і–ї—П –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞? –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–љ–∞ –Љ–∞–Ї—Б–Є–Љ–∞–ї—М–љ–∞—П –њ—А–Њ—З–љ–Њ—Б—В—М –Є –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –і–ї—П —А–∞–±–Њ—В—Л –≤ —Г—Б–ї–Њ–≤–Є—П—Е –≤—Л—Б–Њ–Ї–Є—Е –љ–∞–≥—А—Г–Ј–Њ–Ї, —В–Њ —Б—В–∞–ї—М вАФ —Н—В–Њ —В–Њ, —З—В–Њ –≤–∞–Љ –љ—Г–ґ–љ–Њ. –Т—Л —Г–≤–Є–і–Є—В–µ –µ—С –≤ –Љ–Њ—Б—В–∞—Е, –≤—Л—Б–Њ—В–љ—Л—Е –Ј–і–∞–љ–Є—П—Е –Є –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ–Њ–Љ –Њ–±–Њ—А—Г–і–Њ–≤–∞–љ–Є–Є. –Х—Б–ї–Є –ґ–µ –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–µ–љ—М—И–Є–є –≤–µ—Б, –±–Њ–ї–µ–µ —Г–і–Њ–±–љ–∞—П –≤ –Њ–±—А–∞—Й–µ–љ–Є–Є –Є —В—А–µ–±—Г—О—Й–∞—П –Љ–µ–љ—М—И–µ–≥–Њ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є—П —Б—В–∞–ї—М, —В–Њ –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є —Б—В–∞–љ—Г—В —А–∞–Ј—Г–Љ–љ–Њ–є –∞–ї—М—В–µ—А–љ–∞—В–Є–≤–Њ–є.

–°–Њ–≤–µ—В: –£—З–Є—В—Л–≤–∞–є—В–µ –Њ–±—Й—Г—О —Б—В–Њ–Є–Љ–Њ—Б—В—М –љ–∞ –њ—А–Њ—В—П–ґ–µ–љ–Є–Є –≤—Б–µ–≥–Њ –ґ–Є–Ј–љ–µ–љ–љ–Њ–≥–Њ —Ж–Є–Ї–ї–∞, –∞ –љ–µ —В–Њ–ї—М–Ї–Њ –њ–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ—Г—О —Ж–µ–љ—Г. –Р–ї—О–Љ–Є–љ–Є–є –Љ–Њ–ґ–µ—В —Б—В–Њ–Є—В—М –і–Њ—А–Њ–ґ–µ –љ–∞ –љ–∞—З–∞–ї—М–љ–Њ–Љ —Н—В–∞–њ–µ, –љ–Њ –µ–≥–Њ –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–∞—П —Б—В–Њ–є–Ї–Њ—Б—В—М –Є –љ–Є–Ј–Ї–Є–µ –Ј–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –њ–Њ–Ј–≤–Њ–ї—П—В —Б—Н–Ї–Њ–љ–Њ–Љ–Є—В—М –і–µ–љ—М–≥–Є –≤ –і–Њ–ї–≥–Њ—Б—А–Њ—З–љ–Њ–є –њ–µ—А—Б–њ–µ–Ї—В–Є–≤–µ.

–Т—Л–±–Њ—А —Б–ї–µ–і—Г–µ—В –і–µ–ї–∞—В—М –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ–Є –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Ф–ї—П –њ—А–Њ—З–љ—Л—Е –Ї–∞—А–Ї–∞—Б–Њ–≤ –њ—А–µ–і–њ–Њ—З—В–Є—В–µ–ї—М–љ–µ–µ —Б—В–∞–ї—М. –Ф–ї—П –њ—А–Њ–µ–Ї—В–Њ–≤, –≥–і–µ –≤–∞–ґ–љ—Л –≤–µ—Б, –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–∞—П —Б—В–Њ–є–Ї–Њ—Б—В—М –Є –≥–Є–±–Ї–Њ—Б—В—М –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Є, –ї—Г—З—И–µ –≤—Б–µ–≥–Њ –њ–Њ–і–Њ–є–і—Г—В –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є. –Ю–±–∞ –Љ–∞—В–µ—А–Є–∞–ї–∞ –Є–Љ–µ—О—В —Б–≤–Њ–Є –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞, –њ–Њ—Н—В–Њ–Љ—Г, –њ—А–µ–ґ–і–µ —З–µ–Љ –њ—А–Є–љ–Є–Љ–∞—В—М —А–µ—И–µ–љ–Є–µ, –њ–Њ–і—Г–Љ–∞–є—В–µ –Њ —Б–≤–Њ–Є—Е –њ—А–Є–Њ—А–Є—В–µ—В–∞—Е.

–Ф–µ—А–µ–≤–Њ –њ—А–Њ—В–Є–≤ –∞–ї—О–Љ–Є–љ–Є—П

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞ –і—А–µ–≤–µ—Б–Є–љ—Л

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ, –≤–∞–Љ –љ—А–∞–≤–Є—В—Б—П –≤–љ–µ—И–љ–Є–є –≤–Є–і –Є —В–µ–Ї—Б—В—Г—А–∞ –і–µ—А–µ–≤–∞ –≤ –≤–∞—И–Є—Е –њ—А–Њ–µ–Ї—В–∞—Е. –Ф–µ—А–µ–≤–Њ –њ—А–Є–≤–љ–Њ—Б–Є—В —В–µ–њ–ї–Њ –Є –Ї–ї–∞—Б—Б–Є—З–µ—Б–Ї–Є–є —Б—В–Є–ї—М, –Ї–Њ—В–Њ—А—Л–є —Ж–µ–љ—П—В –Љ–љ–Њ–≥–Є–µ. –Ф–µ—А–µ–≤–Њ –ї–µ–≥–Ї–Њ –њ–Њ–і–і–∞–µ—В—Б—П –Њ–±—А–∞–±–Њ—В–Ї–µ –Є —Е–Њ—А–Њ—И–Њ –њ–Њ–і—Е–Њ–і–Є—В –і–ї—П –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤. –Х—Б–ї–Є –≤—Л —Е–Њ—В–Є—В–µ –њ–Њ–ї—Г—З–Є—В—М –љ–∞—В—Г—А–∞–ї—М–љ—Г—О –Њ—В–і–µ–ї–Ї—Г, –і–µ—А–µ–≤–Њ –њ—А–µ–і–Њ—Б—В–∞–≤–ї—П–µ—В –Љ–љ–Њ–ґ–µ—Б—В–≤–Њ –≤–∞—А–Є–∞–љ—В–Њ–≤. –Ь–љ–Њ–≥–Є–µ —Б—В—А–Њ–Є—В–µ–ї–Є –≤—Л–±–Є—А–∞—О—В –і–µ—А–µ–≤–Њ –Є–Ј-–Ј–∞ –µ–≥–Њ –±–Њ–ї–µ–µ –љ–Є–Ј–Ї–Њ–є –њ–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ–Њ–є —Б—В–Њ–Є–Љ–Њ—Б—В–Є, –Њ—Б–Њ–±–µ–љ–љ–Њ –≤ –ґ–Є–ї–Є—Й–љ–Њ–Љ —Б—В—А–Њ–Є—В–µ–ї—М—Б—В–≤–µ. –Ф–µ—А–µ–≤–Њ –Љ–Њ–ґ–љ–Њ –љ–∞–є—В–Є –њ—А–∞–Ї—В–Є—З–µ—Б–Ї–Є –≤–µ–Ј–і–µ, —З—В–Њ –і–µ–ї–∞–µ—В –µ–≥–Њ —Г–і–Њ–±–љ—Л–Љ –≤—Л–±–Њ—А–Њ–Љ –і–ї—П –љ–µ–±–Њ–ї—М—И–Є—Е –њ—А–Њ–µ–Ї—В–Њ–≤.

–°–ї–∞–±–Њ—Б—В–Є –і—А–µ–≤–µ—Б–Є–љ—Л

–£ –і—А–µ–≤–µ—Б–Є–љ—Л –µ—Б—В—М –љ–µ–Ї–Њ—В–Њ—А—Л–µ –љ–µ–і–Њ—Б—В–∞—В–Ї–Є, –Ї–Њ—В–Њ—А—Л–µ —Б–ї–µ–і—Г–µ—В —Г—З–Є—В—Л–≤–∞—В—М –њ–µ—А–µ–і –њ—А–Є–љ—П—В–Є–µ–Љ —А–µ—И–µ–љ–Є—П. –Ф–µ—А–µ–≤—П–љ–љ—Л–µ —А–∞–Љ—Л –Љ–Њ–≥—Г—В –≤–њ–Є—В—Л–≤–∞—В—М –≤–ї–∞–≥—Г, —З—В–Њ –њ—А–Є–≤–Њ–і–Є—В –Ї –і–µ—Д–Њ—А–Љ–∞—Ж–Є–Є, –≥–љ–Є–µ–љ–Є—О –Є –љ–∞—И–µ—Б—В–≤–Є—О –≤—А–µ–і–Є—В–µ–ї–µ–є. –Т–Њ –≤–ї–∞–ґ–љ–Њ–є —Б—А–µ–і–µ —Н—В–Є –њ—А–Њ–±–ї–µ–Љ—Л —Г—Б—Г–≥—Г–±–ї—П—О—В—Б—П. –Э–µ–Њ–±—Е–Њ–і–Є–Љ–Њ —А–µ–≥—Г–ї—П—А–љ–Њ –Њ–±—А–∞–±–∞—В—Л–≤–∞—В—М –Є–ї–Є –≥–µ—А–Љ–µ—В–Є–Ј–Є—А–Њ–≤–∞—В—М –і—А–µ–≤–µ—Б–Є–љ—Г, —З—В–Њ–±—Л –њ—А–µ–і–Њ—В–≤—А–∞—В–Є—В—М –µ–µ –±—Л—Б—В—А–Њ–µ —А–∞–Ј—А—Г—И–µ–љ–Є–µ. –Я–Њ–Ї—А–∞—Б–Ї–∞, —В–Њ–љ–Є—А–Њ–≤–∞–љ–Є–µ –Є –≥–µ—А–Љ–µ—В–Є–Ј–∞—Ж–Є—П вАФ –≤–∞–ґ–љ—Л–µ —И–∞–≥–Є –і–ї—П –Ј–∞—Й–Є—В—Л –і—А–µ–≤–µ—Б–Є–љ—Л –Њ—В —Б–Њ–ї–љ—Ж–∞ –Є –і–Њ–ґ–і—П. –Х—Б–ї–Є –њ—А–µ–љ–µ–±—А–µ–≥–∞—В—М —Г—Е–Њ–і–Њ–Љ, –і—А–µ–≤–µ—Б–Є–љ–∞ –Љ–Њ–ґ–µ—В –±—Л—Б—В—А–Њ –њ–Њ—В–µ—А—П—В—М —Б–≤–Њ—О –њ—А–Њ—З–љ–Њ—Б—В—М –Є –≤–љ–µ—И–љ–Є–є –≤–Є–і.

–Ф–µ—А–µ–≤—П–љ–љ—Л–µ –Ї–∞—А–Ї–∞—Б—Л, –љ–µ—Б–Љ–Њ—В—А—П –љ–∞ —Б–≤–Њ—О –њ—А–Њ—З–љ–Њ—Б—В—М, –њ–Њ–і–≤–µ—А–ґ–µ–љ—Л —В–∞–Ї–Є–Љ –њ—А–Њ–±–ї–µ–Љ–∞–Љ, –Ї–∞–Ї –і–µ—Д–Њ—А–Љ–∞—Ж–Є—П, –≥–љ–Є–µ–љ–Є–µ –Є –њ–Њ–≤—А–µ–ґ–і–µ–љ–Є—П –љ–∞—Б–µ–Ї–Њ–Љ—Л–Љ–Є, –µ—Б–ї–Є –Ј–∞ –љ–Є–Љ–Є –љ–µ —Г—Е–∞–ґ–Є–≤–∞—В—М –і–Њ–ї–ґ–љ—Л–Љ –Њ–±—А–∞–Ј–Њ–Љ. –†–µ–≥—Г–ї—П—А–љ–Њ–µ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –љ–µ–Њ–±—Е–Њ–і–Є–Љ–Њ –і–ї—П –њ–Њ–і–і–µ—А–ґ–∞–љ–Є—П –і—А–µ–≤–µ—Б–Є–љ—Л –≤ —Е–Њ—А–Њ—И–µ–Љ —Б–Њ—Б—В–Њ—П–љ–Є–Є. –°–Њ –≤—А–µ–Љ–µ–љ–µ–Љ –Ј–∞—В—А–∞—В—Л –љ–∞ —Б–Њ–і–µ—А–ґ–∞–љ–Є–µ –љ–∞–Ї–∞–њ–ї–Є–≤–∞—О—В—Б—П, –Њ—Б–Њ–±–µ–љ–љ–Њ –≤ –Ї–Њ–Љ–Љ–µ—А—З–µ—Б–Ї–Є—Е –Ј–і–∞–љ–Є—П—Е, –≥–і–µ –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є–Љ–µ–µ—В –Ј–љ–∞—З–µ–љ–Є–µ.

–Т—Л–±–Њ—А –Љ–µ–ґ–і—Г –і–µ—А–µ–≤–Њ–Љ –Є –∞–ї—О–Љ–Є–љ–Є–µ–Љ

–Я—А–Є —Б—А–∞–≤–љ–µ–љ–Є–Є –і–µ—А–µ–≤—П–љ–љ—Л—Е –Є –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є –Љ–Њ–ґ–љ–Њ –Ј–∞–Љ–µ—В–Є—В—М —П–≤–љ—Л–µ —А–∞–Ј–ї–Є—З–Є—П. –Р–ї—О–Љ–Є–љ–Є–є –Є–Ј–љ–∞—З–∞–ї—М–љ–Њ —Б—В–Њ–Є—В –і–Њ—А–Њ–ґ–µ, –љ–Њ —Б–Њ –≤—А–µ–Љ–µ–љ–µ–Љ –Ј–∞—В—А–∞—В—Л –љ–∞ –µ–≥–Њ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ —Б–Њ–Ї—А–∞—Й–∞—О—В—Б—П. –Ф–µ—А–µ–≤–Њ –Є–Ј–љ–∞—З–∞–ї—М–љ–Њ –і–µ—И–µ–≤–ї–µ, –љ–Њ —А–µ–Љ–Њ–љ—В –Є —Б–Њ–і–µ—А–ґ–∞–љ–Є–µ –Њ–±—Е–Њ–і—П—В—Б—П –і–Њ—А–Њ–ґ–µ. –Т–Ј–≥–ї—П–љ–Є—В–µ –љ–∞ —Н—В—Г —В–∞–±–ї–Є—Ж—Г:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–Я–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ—Л–µ –Ј–∞—В—А–∞—В—Л

|

–Ч–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ

|

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М

|

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –њ–Њ–≤—В–Њ—А–љ–Њ–≥–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П

|

|

–Ф—А–µ–≤–µ—Б–Є–љ–∞

|

–Э–Є–ґ–µ

|

–°–Њ –≤—А–µ–Љ–µ–љ–µ–Љ —Б—В–∞–љ–Њ–≤–Є—В—Б—П –≤—Л—И–µ

|

–Ь–µ–љ–µ–µ –і–Њ–ї–≥–Њ–≤–µ—З–љ—Л–є

|

–Э–µ—В

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

–Т—Л—И–µ

|

–° —В–µ—З–µ–љ–Є–µ–Љ –≤—А–µ–Љ–µ–љ–Є —Б–љ–Є–ґ–µ–љ–Є–µ

|

–С–Њ–ї–µ–µ –і–Њ–ї–≥–Њ–≤–µ—З–љ—Л–є

|

–Ф–∞

|

–£—Б—В–Њ–є—З–Є–≤–Њ–µ —А–∞–Ј–≤–Є—В–Є–µ —В–Њ–ґ–µ –Є–Љ–µ–µ—В –Ј–љ–∞—З–µ–љ–Є–µ. –Р–ї—О–Љ–Є–љ–Є–є —Б —В–µ–Ї—Б—В—Г—А–Њ–є –і—А–µ–≤–µ—Б–Є–љ—Л –њ–Њ–ї–љ–Њ—Б—В—М—О –њ—А–Є–≥–Њ–і–µ–љ –і–ї—П –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є, –≤ —В–Њ –≤—А–µ–Љ—П –Ї–∞–Ї –љ–∞—В—Г—А–∞–ї—М–љ–∞—П –і—А–µ–≤–µ—Б–Є–љ–∞ –Є–Љ–µ–µ—В –Њ–≥—А–∞–љ–Є—З–µ–љ–љ—Г—О –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є. –Я—А–Њ—Ж–µ—Б—Б –Ј–∞–Ї—Г–њ–Ї–Є –∞–ї—О–Љ–Є–љ–Є—П –Љ–Њ–ґ–µ—В –±—Л—В—М –±–Њ–ї–µ–µ –њ—А–Њ–Ј—А–∞—З–љ—Л–Љ, –Њ—Б–Њ–±–µ–љ–љ–Њ –њ—А–Є –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є–Є –њ–µ—А–µ—А–∞–±–Њ—В–∞–љ–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤. –Ґ—А–∞–і–Є—Ж–Є–Њ–љ–љ–∞—П –і–Њ–±—Л—З–∞ –і—А–µ–≤–µ—Б–Є–љ—Л –Љ–Њ–ґ–µ—В –њ—А–Є–≤–µ—Б—В–Є –Ї –≤—Л—А—Г–±–Ї–µ –ї–µ—Б–Њ–≤ –Є –љ–∞—А—Г—И–µ–љ–Є—О —Б—А–µ–і—Л –Њ–±–Є—В–∞–љ–Є—П.

-

–Р–ї—О–Љ–Є–љ–Є–є —Б —В–µ–Ї—Б—В—Г—А–Њ–є –і—А–µ–≤–µ—Б–Є–љ—Л –њ–Њ–ї–љ–Њ—Б—В—М—О –њ—А–Є–≥–Њ–і–µ–љ –і–ї—П –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є, –≤ —В–Њ –≤—А–µ–Љ—П –Ї–∞–Ї –љ–∞—В—Г—А–∞–ї—М–љ–∞—П –і—А–µ–≤–µ—Б–Є–љ–∞ –Є–Љ–µ–µ—В –Њ–≥—А–∞–љ–Є—З–µ–љ–љ—Л–µ –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В–Є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є.

-

–Я—А–Њ—Ж–µ—Б—Б –Ј–∞–Ї—Г–њ–Ї–Є –∞–ї—О–Љ–Є–љ–Є—П –Љ–Њ–ґ–µ—В –±—Л—В—М –±–Њ–ї–µ–µ –њ—А–Њ–Ј—А–∞—З–љ—Л–Љ, –Њ—Б–Њ–±–µ–љ–љ–Њ –њ—А–Є –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є–Є –њ–µ—А–µ—А–∞–±–Њ—В–∞–љ–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤.

-

–Ґ—А–∞–і–Є—Ж–Є–Њ–љ–љ—Л–µ –Љ–µ—В–Њ–і—Л –і–Њ–±—Л—З–Є –і—А–µ–≤–µ—Б–Є–љ—Л –Љ–Њ–≥—Г—В –њ—А–Є–≤–Њ–і–Є—В—М –Ї –Њ–±–µ–Ј–ї–µ—Б–Є–≤–∞–љ–Є—О –Є –љ–∞—А—Г—И–µ–љ–Є—О —Б—А–µ–і—Л –Њ–±–Є—В–∞–љ–Є—П.

–Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є –њ—А–Њ—Б–ї—Г–ґ–Є—В –і–Њ–ї—М—И–µ, –њ–Њ—В—А–µ–±—Г–µ—В –Љ–µ–љ—М—И–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є—П –Є –±—Г–і–µ—В —Б–њ–Њ—Б–Њ–±—Б—В–≤–Њ–≤–∞—В—М —Н–Ї–Њ–ї–Њ–≥–Є—З–љ–Њ–Љ—Г —Б—В—А–Њ–Є—В–µ–ї—М—Б—В–≤—Г, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАФ —А–∞–Ј—Г–Љ–љ—Л–є –≤—Л–±–Њ—А. –Т—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М, —Б—В–Є–ї—М –Є —Н–Ї–Њ–ї–Њ–≥–Є—З–љ–Њ—Б—В—М –≤ –Њ–і–љ–Њ–Љ –Є–Ј–і–µ–ї–Є–Є.

–Я–ї–∞—Б—В–Є–Ї –њ—А–Њ—В–Є–≤ –∞–ї—О–Љ–Є–љ–Є—П

–Я—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–∞ –њ–ї–∞—Б—В–Є–Ї–∞

–Т—Л –Љ–Њ–ґ–µ—В–µ –њ–Њ–і—Г–Љ–∞—В—М, —З—В–Њ –њ–ї–∞—Б—В–Є–Ї –њ–Њ–і—Е–Њ–і–Є—В —В–Њ–ї—М–Ї–Њ –і–ї—П –ї–µ–≥–Ї–Є—Е —А–∞–±–Њ—В, –љ–Њ –љ–∞ —Б–∞–Љ–Њ–Љ –і–µ–ї–µ –Њ–љ –Њ–±–ї–∞–і–∞–µ—В —А—П–і–Њ–Љ —Б—Г—Й–µ—Б—В–≤–µ–љ–љ—Л—Е –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤. –Я–ї–∞—Б—В–Є–Ї –ї–µ–≥–Ї–Њ —Д–Њ—А–Љ—Г–µ—В—Б—П –≤ —А–∞–Ј–ї–Є—З–љ—Л–µ —Д–Њ—А–Љ—Л, —З—В–Њ –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –≥–Є–±–Ї–Њ—Б—В—М –і–ї—П —Б–Њ–Ј–і–∞–љ–Є—П –Ї—А–µ–∞—В–Є–≤–љ—Л—Е –і–Є–Ј–∞–є–љ–Њ–≤. –Т—Л –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М –Є–Ј —И–Є—А–Њ–Ї–Њ–≥–Њ —Б–њ–µ–Ї—В—А–∞ —Ж–≤–µ—В–Њ–≤ –Є –≤–∞—А–Є–∞–љ—В–Њ–≤ –Њ—В–і–µ–ї–Ї–Є. –Я–ї–∞—Б—В–Є–Ї —Е–Њ—А–Њ—И–Њ –њ–Њ–≥–ї–Њ—Й–∞–µ—В —Г–і–∞—А—Л, —З—В–Њ –і–µ–ї–∞–µ—В –µ–≥–Њ –Њ—В–ї–Є—З–љ—Л–Љ –Љ–∞—В–µ—А–Є–∞–ї–Њ–Љ –і–ї—П –њ—А–Є–Љ–µ–љ–µ–љ–Є–є, –≥–і–µ –≤–∞–ґ–љ–∞ —Г–і–∞—А–Њ–њ—А–Њ—З–љ–Њ—Б—В—М. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є –љ–µ —А–ґ–∞–≤–µ–µ—В –Є –љ–µ –њ–Њ–і–≤–µ—А–≥–∞–µ—В—Б—П –Ї–Њ—А—А–Њ–Ј–Є–Є, –њ–ї–∞—Б—В–Є–Ї –Є–і–µ–∞–ї—М–љ–Њ –њ–Њ–і–Њ–є–і–µ—В. –Ъ—А–Њ–Љ–µ —В–Њ–≥–Њ, –≤—Л —Н–Ї–Њ–љ–Њ–Љ–Є—В–µ –і–µ–љ—М–≥–Є –љ–∞ –љ–∞—З–∞–ї—М–љ–Њ–Љ —Н—В–∞–њ–µ, –њ–Њ—Б–Ї–Њ–ї—М–Ї—Г –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–Њ –њ–ї–∞—Б—В–Є–Ї–∞ –Њ–±—Л—З–љ–Њ –Њ–±—Е–Њ–і–Є—В—Б—П –і–µ—И–µ–≤–ї–µ, —З–µ–Љ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–Њ –∞–ї—О–Љ–Є–љ–Є—П.

-

–С–ї–∞–≥–Њ–і–∞—А—П —Б–≤–Њ–µ–є —Н–ї–∞—Б—В–Є—З–љ–Њ—Б—В–Є –њ–ї–∞—Б—В–Є–Ї –ї—Г—З—И–µ –њ–Њ–≥–ї–Њ—Й–∞–µ—В —Г–і–∞—А—Л, —З–µ–Љ –Љ–µ—В–∞–ї–ї—Л.

-

–Т—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –±–Њ–ї–µ–µ –љ–Є–Ј–Ї–Є–µ –њ–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ—Л–µ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–µ–љ–љ—Л–µ –Ј–∞—В—А–∞—В—Л.

-

–Я–ї–∞—Б—В–Є–Ї –ї–µ–≥—З–µ –Љ–љ–Њ–≥–Є—Е –і—А—Г–≥–Є—Е —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤.

–Э–µ–і–Њ—Б—В–∞—В–Ї–Є –њ–ї–∞—Б—В–Є–Ї–∞

–£ –њ–ї–∞—Б—В–Є–Ї–∞ –µ—Б—В—М —Б–≤–Њ–Є –Њ–≥—А–∞–љ–Є—З–µ–љ–Є—П, –Њ—Б–Њ–±–µ–љ–љ–Њ –µ—Б–ї–Є —Б—А–∞–≤–љ–Є–≤–∞—В—М –µ–≥–Њ —Б –∞–ї—О–Љ–Є–љ–Є–µ–Љ. –Т—Л –Ј–∞–Љ–µ—В–Є—В–µ, —З—В–Њ –њ–ї–∞—Б—В–Є–Ї –љ–µ –Љ–Њ–ґ–µ—В —Б—А–∞–≤–љ–Є—В—М—Б—П –њ–Њ –њ—А–Њ—З–љ–Њ—Б—В–Є –Є –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В–Є —Б –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–Љ–Є –њ—А–Њ—Д–Є–ї—П–Љ–Є. –Я—А–Њ—З–љ–Њ—Б—В—М –љ–∞ —А–∞—Б—В—П–ґ–µ–љ–Є–µ —А–∞—Б–њ—А–Њ—Б—В—А–∞–љ–µ–љ–љ—Л—Е –њ–ї–∞—Б—В–Є–Ї–Њ–≤, —В–∞–Ї–Є—Е –Ї–∞–Ї –Я–Т–• –Є–ї–Є –њ–Њ–ї–Є—Н—В–Є–ї–µ–љ, —Б–Њ—Б—В–∞–≤–ї—П–µ—В –Њ—В 20 –і–Њ 60 –Ь–Я–∞, –≤ —В–Њ –≤—А–µ–Љ—П –Ї–∞–Ї —Г –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е —Б–њ–ї–∞–≤–Њ–≤ —Н—В–Њ—В –њ–Њ–Ї–∞–Ј–∞—В–µ–ї—М –Ї–Њ–ї–µ–±–ї–µ—В—Б—П –Њ—В 70 –і–Њ 700 –Ь–Я–∞. –≠—В–Њ –Њ–Ј–љ–∞—З–∞–µ—В, —З—В–Њ –∞–ї—О–Љ–Є–љ–Є–є –ї—Г—З—И–µ –≤—Л–і–µ—А–ґ–Є–≤–∞–µ—В –±–Њ–ї—М—И–Є–µ –љ–∞–≥—А—Г–Ј–Ї–Є –Є –њ–Њ–≤—В–Њ—А—П—О—Й–Є–µ—Б—П –љ–∞–њ—А—П–ґ–µ–љ–Є—П. –Я–ї–∞—Б—В–Є–Ї –Љ–Њ–ґ–µ—В –і–µ—Д–Њ—А–Љ–Є—А–Њ–≤–∞—В—М—Б—П –Є–ї–Є —В—А–µ—Б–љ—Г—В—М, –µ—Б–ї–Є –љ–∞ –љ–µ–≥–Њ –≤–Њ–Ј–і–µ–є—Б—В–≤–Њ–≤–∞—В—М —Б–ї–Є—И–Ї–Њ–Љ –±–Њ–ї—М—И–Њ–є –≤–µ—Б. –°–Њ –≤—А–µ–Љ–µ–љ–µ–Љ –≤–Њ–Ј–і–µ–є—Б—В–≤–Є–µ —Б–Њ–ї–љ–µ—З–љ–Њ–≥–Њ —Б–≤–µ—В–∞ –Є –њ–Њ–≥–Њ–і–љ—Л—Е —Г—Б–ї–Њ–≤–Є–є –Љ–Њ–ґ–µ—В —Б–і–µ–ї–∞—В—М –њ–ї–∞—Б—В–Є–Ї —Е—А—Г–њ–Ї–Є–Љ.

–Ф–∞–≤–∞–є—В–µ –њ–Њ—Б–Љ–Њ—В—А–Є–Љ, –Ї–∞–Ї –њ–ї–∞—Б—В–Є–Ї –Є –∞–ї—О–Љ–Є–љ–Є–є –њ—А–Њ—П–≤–ї—П—О—В —Б–µ–±—П –≤ –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ–Њ–Љ –њ—А–Є–Љ–µ–љ–µ–љ–Є–Є:

|

–§–∞–Ї—В–Њ—А

|

–Я–ї–∞—Б—В–Є–Ї

|

–Р–ї—О–Љ–Є–љ–Є–є

|

|

–Я–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ—Л–µ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–µ–љ–љ—Л–µ –Ј–∞—В—А–∞—В—Л

|

–Э–Є–ґ–µ

|

–Т—Л—И–µ

|

|

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М

|

–°–µ—А–µ–і–Є–љ–∞

|

–Т—Л—Б–Њ–Ї–Є–є

|

|

–≠—Д—Д–µ–Ї—В–Є–≤–љ–Њ—Б—В—М –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є

|

–£–Љ–µ—А–µ–љ–љ—Л–є

|

–Ю—В–ї–Є—З–љ—Л–є

|

–Я–µ—А–µ—А–∞–±–Њ—В–Ї–∞ –њ–ї–∞—Б—В–Є–Ї–∞ —В–∞–Ї–ґ–µ —Б–Њ–њ—А—П–ґ–µ–љ–∞ —Б –њ—А–Њ–±–ї–µ–Љ–∞–Љ–Є. –С–Њ–ї—М—И–Є–љ—Б—В–≤–Њ –≤–Є–і–Њ–≤ –њ–ї–∞—Б—В–Є–Ї–∞ –Є–Љ–µ—О—В –љ–Є–Ј–Ї–Є–є —Г—А–Њ–≤–µ–љ—М –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є, —З—В–Њ –њ—А–Є–≤–Њ–і–Є—В –Ї –Њ–±—А–∞–Ј–Њ–≤–∞–љ–Є—О –Њ—В—Е–Њ–і–Њ–≤ –Є –Ј–∞–≥—А—П–Ј–љ–µ–љ–Є—О –Њ–Ї—А—Г–ґ–∞—О—Й–µ–є —Б—А–µ–і—Л. –Р–ї—О–Љ–Є–љ–Є–є, –љ–∞–њ—А–Њ—В–Є–≤, –і–µ–Љ–Њ–љ—Б—В—А–Є—А—Г–µ—В –Њ—В–ї–Є—З–љ—Г—О —Н—Д—Д–µ–Ї—В–Є–≤–љ–Њ—Б—В—М –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є –Є –±–Њ–ї–µ–µ –≤—Л—Б–Њ–Ї–Є–µ –њ–Њ–Ї–∞–Ј–∞—В–µ–ї–Є —Г—В–Є–ї–Є–Ј–∞—Ж–Є–Є.

–Т—Л–±–Њ—А –Љ–µ–ґ–і—Г –њ–ї–∞—Б—В–Є–Ї–Њ–Љ –Є –∞–ї—О–Љ–Є–љ–Є–µ–Љ

–Я—А–Є –≤—Л–±–Њ—А–µ –Љ–µ–ґ–і—Г –њ–ї–∞—Б—В–Є–Ї–Њ–Љ –Є –∞–ї—О–Љ–Є–љ–Є–µ–Љ –љ–µ–Њ–±—Е–Њ–і–Є–Љ–Њ —Г—З–Є—В—Л–≤–∞—В—М –њ–Њ—В—А–µ–±–љ–Њ—Б—В–Є –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є –ї–µ–≥–Ї–Њ –њ–Њ–і–і–∞–µ—В—Б—П —Д–Њ—А–Љ–Њ–≤–Ї–µ –Є –Є–Љ–µ–µ—В –±–Њ–ї–µ–µ –љ–Є–Ј–Ї—Г—О –њ–µ—А–≤–Њ–љ–∞—З–∞–ї—М–љ—Г—О —Б—В–Њ–Є–Љ–Њ—Б—В—М, –њ–ї–∞—Б—В–Є–Ї –Љ–Њ–ґ–µ—В –≤–∞–Љ –њ–Њ–і–Њ–є—В–Є. –Х—Б–ї–Є –ґ–µ –≤–∞–Љ –љ–µ–Њ–±—Е–Њ–і–Є–Љ—Л –њ—А–Њ—З–љ–Њ—Б—В—М, –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є –ї—Г—З—И–Є–µ –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В–Є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАФ –±–Њ–ї–µ–µ —А–∞–Ј—Г–Љ–љ—Л–є –≤—Л–±–Њ—А. –Р–ї—О–Љ–Є–љ–Є–є –ї—Г—З—И–µ –≤—Л–і–µ—А–ґ–Є–≤–∞–µ—В —Ж–Є–Ї–ї–Є—З–µ—Б–Ї–Є–µ –љ–∞–≥—А—Г–Ј–Ї–Є –Є —Б–Є–ї—М–љ–Њ–µ —Б–ґ–∞—В–Є–µ, —З—В–Њ –і–µ–ї–∞–µ—В –µ–≥–Њ –Є–і–µ–∞–ї—М–љ—Л–Љ –і–ї—П –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є–Њ–љ–љ–Њ–≥–Њ –њ—А–Є–Љ–µ–љ–µ–љ–Є—П. –Ъ—А–Њ–Љ–µ —В–Њ–≥–Њ, –≤—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –±–Њ–ї–µ–µ —Н–Ї–Њ–ї–Њ–≥–Є—З–љ—Л–є –≤–∞—А–Є–∞–љ—В, –њ–Њ—Б–Ї–Њ–ї—М–Ї—Г –∞–ї—О–Љ–Є–љ–Є–є –Є–Љ–µ–µ—В –±–Њ–ї–µ–µ –≤—Л—Б–Њ–Ї–Є–µ –њ–Њ–Ї–∞–Ј–∞—В–µ–ї–Є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є.

–°–Њ–≤–µ—В: –£—З–Є—В—Л–≤–∞–є—В–µ –Ї–Њ–ї–Є—З–µ—Б—В–≤–Њ —Н–љ–µ—А–≥–Є–Є, –Ј–∞—В—А–∞—З–Є–≤–∞–µ–Љ–Њ–є –љ–∞ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–Њ. –Ф–ї—П –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–∞ –Њ–і–љ–Њ–≥–Њ –Ї–Є–ї–Њ–≥—А–∞–Љ–Љ–∞ –∞–ї—О–Љ–Є–љ–Є—П —В—А–µ–±—Г–µ—В—Б—П –±–Њ–ї—М—И–µ —Н–ї–µ–Ї—В—А–Њ—Н–љ–µ—А–≥–Є–Є, —З–µ–Љ –і–ї—П –њ–ї–∞—Б—В–Є–Ї–∞, –љ–Њ –њ—А–Є —Н—В–Њ–Љ –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В—Б—П –±–Њ–ї–µ–µ –і–ї–Є—В–µ–ї—М–љ—Л–є —Б—А–Њ–Ї —Б–ї—Г–ґ–±—Л –Є –ї—Г—З—И–∞—П –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є.

–Т–∞–Љ —Б–ї–µ–і—Г–µ—В –≤–Ј–≤–µ—Б–Є—В—М –≤—Б–µ ¬Ђ–Ј–∞¬ї –Є ¬Ђ–њ—А–Њ—В–Є–≤¬ї –Њ–±–Њ–Є—Е –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤. –Т–∞—И –Њ–Ї–Њ–љ—З–∞—В–µ–ї—М–љ—Л–є –≤—Л–±–Њ—А –Ј–∞–≤–Є—Б–Є—В –Њ—В –±–∞–ї–∞–љ—Б–∞ –Љ–µ–ґ–і—Г —Б—В–Њ–Є–Љ–Њ—Б—В—М—О, –њ—А–Њ–Є–Ј–≤–Њ–і–Є—В–µ–ї—М–љ–Њ—Б—В—М—О –Є –≤–Њ–Ј–і–µ–є—Б—В–≤–Є–µ–Љ –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г.

–§–∞–Ї—В–Њ—А—Л –≤—Л–±–Њ—А–∞ –Љ–∞—В–µ—А–Є–∞–ї–Њ–≤

–°–Њ–Њ–±—А–∞–ґ–µ–љ–Є—П —Б—В–Њ–Є–Љ–Њ—Б—В–Є

–Я—А–Є –њ–ї–∞–љ–Є—А–Њ–≤–∞–љ–Є–Є –њ—А–Њ–µ–Ї—В–∞ —Б—В–Њ–Є–Љ–Њ—Б—В—М —З–∞—Б—В–Њ —П–≤–ї—П–µ—В—Б—П –Њ–њ—А–µ–і–µ–ї—П—О—Й–Є–Љ —Д–∞–Ї—В–Њ—А–Њ–Љ –њ—А–Є –њ—А–Є–љ—П—В–Є–Є —А–µ—И–µ–љ–Є–є. –Т–∞–Љ –љ—Г–ґ–љ–Њ –Ј–љ–∞—В—М, –≤–Њ —Б–Ї–Њ–ї—М–Ї–Њ –Њ–±–Њ–є–і–µ—В—Б—П –Ї–∞–ґ–і—Л–є –Љ–∞—В–µ—А–Є–∞–ї –≤ –і–Њ–ї–≥–Њ—Б—А–Њ—З–љ–Њ–є –њ–µ—А—Б–њ–µ–Ї—В–Є–≤–µ. –Т–Ј–≥–ї—П–љ–Є—В–µ –љ–∞ —Н—В–Њ —Б—А–∞–≤–љ–µ–љ–Є–µ:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–°—А–µ–і–љ—П—П —Б—В–Њ–Є–Љ–Њ—Б—В—М (–Ј–∞ –њ–Њ–≥–Њ–љ–љ—Л–є –Љ–µ—В—А)

|

–Ю–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ

|

–Я—А–Њ–і–Њ–ї–ґ–Є—В–µ–ї—М–љ–Њ—Б—В—М –ґ–Є–Ј–љ–Є

|

|

–Ф—А–µ–≤–µ—Б–Є–љ–∞ (–Њ–±—А–∞–±–Њ—В–∞–љ–љ–∞—П)

|

3вАУ6 –і–Њ–ї–ї–∞—А–Њ–≤

|

–†–µ–≥—Г–ї—П—А–љ–∞—П –≥–µ—А–Љ–µ—В–Є–Ј–∞—Ж–Є—П, –њ–Њ–і–≤–µ—А–ґ–µ–љ –≥–љ–Є–µ–љ–Є—О

|

10вАУ15 –ї–µ—В

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

6вАУ12 –і–Њ–ї–ї–∞—А–Њ–≤

|

–Э–Є–Ј–Ї–Є–µ –Ј–∞—В—А–∞—В—Л –љ–∞ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ

|

30вАУ50+ –ї–µ—В

|

–Р–ї—О–Љ–Є–љ–Є–є –Њ–±—Е–Њ–і–Є—В—Б—П –і–Њ—А–Њ–ґ–µ –љ–∞ –љ–∞—З–∞–ї—М–љ–Њ–Љ —Н—В–∞–њ–µ, –љ–Њ —Н–Ї–Њ–љ–Њ–Љ–Є—В –љ–∞ —А–µ–Љ–Њ–љ—В–µ –Є –Ј–∞–Љ–µ–љ–µ. –Ф–ї–Є—В–µ–ї—М–љ—Л–є —Б—А–Њ–Ї —Б–ї—Г–ґ–±—Л –Є –љ–Є–Ј–Ї–Є–µ –Ј–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ –і–µ–ї–∞—О—В –µ–≥–Њ —А–∞–Ј—Г–Љ–љ–Њ–є –Є–љ–≤–µ—Б—В–Є—Ж–Є–µ–є, –µ—Б–ї–Є –≤–∞—Б –≤–Њ–ї–љ—Г–µ—В –і–Њ–ї–≥–Њ—Б—А–Њ—З–љ–∞—П —Н–Ї–Њ–ї–Њ–≥–Є—З–љ–Њ—Б—В—М. –Т—Л –Є–Ј–±–µ–≥–∞–µ—В–µ —З–∞—Б—В–Њ–≥–Њ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є—П, –∞ –Ј–љ–∞—З–Є—В, –Є –њ—А–Њ–±–ї–µ–Љ –≤ –±—Г–і—Г—Й–µ–Љ.

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є–Љ–µ–µ—В –Ј–љ–∞—З–µ–љ–Є–µ, –µ—Б–ї–Є –≤—Л —Е–Њ—В–Є—В–µ, —З—В–Њ–±—Л –≤–∞—И –њ—А–Њ–µ–Ї—В –њ—А–Њ—Б–ї—Г–ґ–Є–ї –і–Њ–ї–≥–Њ. –Т–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є –≤—Л–і–µ—А–ґ–Є—В –µ–ґ–µ–і–љ–µ–≤–љ—Л–є –Є–Ј–љ–Њ—Б. –Т–Њ—В –Ї–∞–Ї —Б—А–∞–≤–љ–Є–≤–∞—О—В—Б—П —А–∞—Б–њ—А–Њ—Б—В—А–∞–љ–µ–љ–љ—Л–µ –≤–∞—А–Є–∞–љ—В—Л:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М

|

–Я—А–Њ–і–Њ–ї–ґ–Є—В–µ–ї—М–љ–Њ—Б—В—М –ґ–Є–Ј–љ–Є

|

–Я–Њ—В—А–µ–±–љ–Њ—Б—В–Є –≤ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–Љ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–Є

|

|

–Ф—А–µ–≤–µ—Б–Є–љ–∞

|

–Э–Є–Ј–Ї–Є–є

|

–Ъ–Њ—А–Њ—В–Ї–Є–є

|

–Т—Л—Б–Њ–Ї–Є–є (—З–∞—Б—В–∞—П –Ј–∞–Љ–µ–љ–∞)

|

|

–°—В–∞–ї—М

|

–Ю—З–µ–љ—М –≤—Л—Б–Њ–Ї–Є–є

|

–°–Њ—В–љ–Є –њ—А–Є–Љ–µ–љ–µ–љ–Є–є

|

–Э–Є–Ј–Ї–Є–є —Г—А–Њ–≤–µ–љ—М –Ї–Њ—А—А–Њ–Ј–Є–Є (—В—А–µ–±—Г–µ—В –∞–љ—В–Є–Ї–Њ—А—А–Њ–Ј–Є–є–љ–Њ–≥–Њ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є—П)

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

–Т—Л—Б–Њ–Ї–Є–є

|

–Ф–ї–Є–љ–љ—Л–є

|

–Э–Є–Ј–Ї–Є–є (–љ–Њ —А–Є—Б–Ї –Ї—А–∞–ґ–Є)

|

–Р–ї—О–Љ–Є–љ–Є–є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –љ–∞–і–µ–ґ–љ—Г—О –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є –Љ–Є–љ–Є–Љ–∞–ї—М–љ–Њ–µ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ. –Т–∞–Љ –љ–µ –њ—А–Є–і–µ—В—Б—П –±–µ—Б–њ–Њ–Ї–Њ–Є—В—М—Б—П –Њ —А–ґ–∞–≤—З–Є–љ–µ –Є–ї–Є –≥–љ–Є–µ–љ–Є–Є. –Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–µ–љ –Љ–∞—В–µ—А–Є–∞–ї, –Ї–Њ—В–Њ—А—Л–є —Б–Њ—Е—А–∞–љ–Є—В —Б–≤–Њ—О –њ—А–Њ—З–љ–Њ—Б—В—М –Є –≤–љ–µ—И–љ–Є–є –≤–Є–і, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАФ —Н—В–Њ —В–Њ, —З—В–Њ –≤–∞–Љ –љ—Г–ґ–љ–Њ.

–Т–Њ–Ј–і–µ–є—Б—В–≤–Є–µ –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ, –≤–∞—Б –Є–љ—В–µ—А–µ—Б—Г–µ—В, –Ї–∞–Ї –≤–∞—И –≤—Л–±–Њ—А –≤–ї–Є—П–µ—В –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г. –Ф–ї—П –Љ–љ–Њ–≥–Є—Е —Б—В—А–Њ–Є—В–µ–ї–µ–є —Б–µ–≥–Њ–і–љ—П —Г—Б—В–Њ–є—З–Є–≤–Њ–µ —А–∞–Ј–≤–Є—В–Є–µ –Є–Љ–µ–µ—В –Њ–≥—А–Њ–Љ–љ–Њ–µ –Ј–љ–∞—З–µ–љ–Є–µ. –Т–Ј–≥–ї—П–љ–Є—В–µ –љ–∞ —Н—В—Г —В–∞–±–ї–Є—Ж—Г:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–Я–Њ—В—А–µ–±–љ–Њ—Б—В—М –≤ —Н–љ–µ—А–≥–Є–Є –і–ї—П –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–∞

|

–Т–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є

|

–Т–Њ–Ј–і–µ–є—Б—В–≤–Є–µ –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

5% —Н–љ–µ—А–≥–Є–Є, –≤—Л—А–∞–±–∞—В—Л–≤–∞–µ–Љ–Њ–є –њ—А–Є –љ–Њ–≤–Њ–Љ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–µ

|

–Я—А–∞–Ї—В–Є—З–µ—Б–Ї–Є –±–µ—Б–Ї–Њ–љ–µ—З–љ—Л–є

|

–°–љ–Є–ґ–µ–љ–Є–µ –≤—Л–±—А–Њ—Б–Њ–≤ —Г–≥–ї–µ–Ї–Є—Б–ї–Њ–≥–Њ –≥–∞–Ј–∞, –Љ–∞–ї—Л–є –≤–µ—Б —Г–Љ–µ–љ—М—И–∞–µ—В –≤—Л–±—А–Њ—Б—Л –Њ—В —В—А–∞–љ—Б–њ–Њ—А—В–∞.

|

|

–°—В–∞–ї—М

|

–Т—Л—И–µ, —З–µ–Љ –∞–ї—О–Љ–Є–љ–Є–є

|

–Ь–µ–љ–µ–µ —Н–љ–µ—А–≥–Њ—Н—Д—Д–µ–Ї—В–Є–≤–љ—Л–є

|

–С–Њ–ї–µ–µ –≤—Л—Б–Њ–Ї–Њ–µ –≤–Њ–Ј–і–µ–є—Б—В–≤–Є–µ –љ–∞ –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г –≤ –њ—А–Њ—Ж–µ—Б—Б–µ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–∞ –Є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є.

|

|

–Я–ї–∞—Б—В–Є–Ї

|

–Т—Л—Б–Њ–Ї–Њ–µ —Н–љ–µ—А–≥–Њ–њ–Њ—В—А–µ–±–ї–µ–љ–Є–µ –Є –≤—Л–±—А–Њ—Б—Л

|

–°–ї–Њ–ґ–љ–Њ –њ–µ—А–µ—А–∞–±–∞—В—Л–≤–∞—В—М

|

–Ю—Б–љ–Њ–≤–љ–Њ–є –Є—Б—В–Њ—З–љ–Є–Ї –≤—Л–±—А–Њ—Б–Њ–≤ –њ–∞—А–љ–Є–Ї–Њ–≤—Л—Е –≥–∞–Ј–Њ–≤

|

|

–Ф—А–µ–≤–µ—Б–Є–љ–∞

|

–Т–Њ–Ј–Њ–±–љ–Њ–≤–ї—П–µ–Љ—Л–є —А–µ—Б—Г—А—Б, –љ–Њ –Љ–Њ–ґ–µ—В –њ—А–Є–≤–µ—Б—В–Є –Ї –≤—Л—А—Г–±–Ї–µ –ї–µ—Б–Њ–≤.

|

–Э/–Ф

|

–Я–Њ—В–µ–љ—Ж–Є–∞–ї—М–љ–∞—П –њ–Њ—В–µ—А—П —Б—А–µ–і—Л –Њ–±–Є—В–∞–љ–Є—П

|

–Р–ї—О–Љ–Є–љ–Є–є –≤—Л–і–µ–ї—П–µ—В—Б—П —Б–≤–Њ–µ–є —Н–Ї–Њ–ї–Њ–≥–Є—З–љ–Њ—Б—В—М—О. –Ю–љ –Њ–±–µ—Б–њ–µ—З–Є–≤–∞–µ—В –њ—А–∞–Ї—В–Є—З–µ—Б–Ї–Є –љ–µ–Њ–≥—А–∞–љ–Є—З–µ–љ–љ—Г—О –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –≤—В–Њ—А–Є—З–љ–Њ–є –њ–µ—А–µ—А–∞–±–Њ—В–Ї–Є –Є —Б–љ–Є–ґ–∞–µ—В –≤—Л–±—А–Њ—Б—Л —Г–≥–ї–µ–Ї–Є—Б–ї–Њ–≥–Њ –≥–∞–Ј–∞. –Т—Л–±–Њ—А –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л—Е –њ—А–Њ—Д–Є–ї–µ–є –њ–Њ–Љ–Њ–≥–∞–µ—В –њ–Њ–і–і–µ—А–ґ–Є–≤–∞—В—М –і–Њ–ї–≥–Њ—Б—А–Њ—З–љ—Г—О —Г—Б—В–Њ–є—З–Є–≤–Њ—Б—В—М –Є –Ј–∞—Й–Є—Й–∞—В—М –Њ–Ї—А—Г–ґ–∞—О—Й—Г—О —Б—А–µ–і—Г.

–У–Є–±–Ї–Њ—Б—В—М –і–Є–Ј–∞–є–љ–∞

–Т—Л —Е–Њ—В–Є—В–µ, —З—В–Њ–±—Л –≤–∞—И –њ—А–Њ–µ–Ї—В –≤—Л–≥–ї—П–і–µ–ї –≤–µ–ї–Є–Ї–Њ–ї–µ–њ–љ–Њ –Є —А–∞–±–Њ—В–∞–ї –±–µ–Ј—Г–њ—А–µ—З–љ–Њ. –У–Є–±–Ї–Њ—Б—В—М –і–Є–Ј–∞–є–љ–∞ –њ–Њ–Ј–≤–Њ–ї—П–µ—В —Б–Њ–Ј–і–∞–≤–∞—В—М —Г–љ–Є–Ї–∞–ї—М–љ—Л–µ —Д–Њ—А–Љ—Л –Є –Њ—В–і–µ–ї–Ї—Г. –Т–Њ—В –Ї–∞–Ї –≤—Л–≥–ї—П–і—П—В —А–∞–Ј–ї–Є—З–љ—Л–µ –Љ–∞—В–µ—А–Є–∞–ї—Л:

|

–Ь–∞—В–µ—А–Є–∞–ї

|

–У–Є–±–Ї–Њ—Б—В—М –і–Є–Ј–∞–є–љ–∞

|

–°–Є–ї–∞

|

–Ь–∞—Б—Б–∞

|

–Я–∞—А–∞–Љ–µ—В—А—Л –љ–∞—Б—В—А–Њ–є–Ї–Є

|

|

–Р–ї—О–Љ–Є–љ–Є–є

|

–Т—Л—Б–Њ–Ї–Є–є

|

–£–Љ–µ—А–µ–љ–љ—Л–є

|

–°–≤–µ—В

|

–°–ї–Њ–ґ–љ—Л–µ —Д–Њ—А–Љ—Л, —А–∞–Ј–љ–Њ–Њ–±—А–∞–Ј–љ—Л–µ –≤–∞—А–Є–∞–љ—В—Л –Њ—В–і–µ–ї–Ї–Є.

|

|

–°—В–∞–ї—М

|

–£–Љ–µ—А–µ–љ–љ—Л–є

|

–Т—Л—Б–Њ–Ї–Є–є

|

–Ґ—П–ґ–µ–ї—Л–є

|

–Ю–≥—А–∞–љ–Є—З–µ–љ–љ–Њ–µ –Ї–Њ–ї–Є—З–µ—Б—В–≤–Њ —Д–Њ—А–Љ, –Љ–µ–љ—М—И–µ –≤–∞—А–Є–∞–љ—В–Њ–≤ –Њ—В–і–µ–ї–Ї–Є.

|

|

–Ф—А–µ–≤–µ—Б–Є–љ–∞

|

–£–Љ–µ—А–µ–љ–љ—Л–є

|

–Э–Є–Ј–Ї–Є–є

|

–°–≤–µ—В

|

–Ю–≥—А–∞–љ–Є—З–µ–љ–љ—Л–є –≤—Л–±–Њ—А —Д–Њ—А–Љ, –љ–∞—В—Г—А–∞–ї—М–љ–∞—П –Њ—В–і–µ–ї–Ї–∞.

|

|

–Я–ї–∞—Б—В–Є–Ї

|

–Э–Є–Ј–Ї–Є–є

|

–Э–Є–Ј–Ї–Є–є

|

–°–≤–µ—В

|

–Я—А–Њ—Б—В—Л–µ —Д–Њ—А–Љ—Л, –Њ–≥—А–∞–љ–Є—З–µ–љ–љ—Л–є –≤—Л–±–Њ—А –Њ—В–і–µ–ї–Ї–Є.

|

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—В –±—Л—Б—В—А—Г—О –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ—Г—О –љ–∞—Б—В—А–Њ–є–Ї—Г. –Т—Л –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М –Є–Ј –Љ–љ–Њ–ґ–µ—Б—В–≤–∞ –≤–∞—А–Є–∞–љ—В–Њ–≤ –Њ—В–і–µ–ї–Ї–Є –Є —Д–Њ—А–Љ. –Ґ–∞–Ї–Є–µ –њ–Њ—Б—В–∞–≤—Й–Є–Ї–Є, –Ї–∞–Ї...

–У—Г–∞–љ –ѓ –Р–ї—О–Љ–Є–љ–Є–µ–≤–∞—П –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ–Њ—Б—В—М –Ы—В–і.

–Ь—Л –њ—А–µ–і–ї–∞–≥–∞–µ–Љ —А–∞–Ј–ї–Є—З–љ—Л–µ –≤–∞—А–Є–∞–љ—В—Л –Њ–±—А–∞–±–Њ—В–Ї–Є –њ–Њ–≤–µ—А—Е–љ–Њ—Б—В–Є, –≤—Л–±–Њ—А —Б–њ–ї–∞–≤–Њ–≤ –Є —Г—Б–ї—Г–≥–Є –њ–Њ –Є–Ј–≥–Њ—В–Њ–≤–ї–µ–љ–Є—О. –Т—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –±—Л—Б—В—А—Г—О –Є–љ–і–Є–≤–Є–і—Г–∞–ї–Є–Ј–∞—Ж–Є—О –Є –≥–Є–±–Ї–Њ—Б—В—М –і–ї—П –ї—О–±–Њ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Ш–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ—Л–є –њ–Њ–і—Е–Њ–і –њ–Њ–Љ–Њ–≥–∞–µ—В –њ–Њ–і–Њ–±—А–∞—В—М –Љ–∞—В–µ—А–Є–∞–ї –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б –њ–Њ—В—А–µ–±–љ–Њ—Б—В—П–Љ–Є –Є —Б—В–Є–ї–µ–Љ –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞.

–°–Њ–≤–µ—В: –°–Њ—В—А—Г–і–љ–Є—З–µ—Б—В–≤–Њ —Б –њ–Њ—Б—В–∞–≤—Й–Є–Ї–Њ–Љ, –њ—А–µ–і–ї–∞–≥–∞—О—Й–Є–Љ –Ї–∞—З–µ—Б—В–≤–µ–љ–љ—Г—О –њ–Њ–і–і–µ—А–ґ–Ї—Г –Є –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В–Є –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ–Њ–є –љ–∞—Б—В—А–Њ–є–Ї–Є, —Б–і–µ–ї–∞–µ—В –≤–∞—И –њ—А–Њ–µ–Ї—В –±–Њ–ї–µ–µ –њ–ї–∞–≤–љ—Л–Љ –Є —Г—Б–њ–µ—И–љ—Л–Љ.

–Т—Л —Г–ґ–µ –≤–Є–і–µ–ї–Є, –Ї–∞–Ї –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є —Б–Њ–Њ—В–љ–Њ—Б—П—В—Б—П —Б–Њ —Б—В–∞–ї—М–љ—Л–Љ–Є, –і–µ—А–µ–≤—П–љ–љ—Л–Љ–Є –Є –њ–ї–∞—Б—В–Є–Ї–Њ–≤—Л–Љ–Є. –Ф–ї—П –Ї—А–∞—В–Ї–Њ–≥–Њ –Њ–±–Ј–Њ—А–∞ –Њ–Ј–љ–∞–Ї–Њ–Љ—М—В–µ—Б—М —Б —Н—В–Њ–є —В–∞–±–ї–Є—Ж–µ–є:

|

–Ъ–ї—О—З–µ–≤–Њ–µ –њ—А–µ–Є–Љ—Г—Й–µ—Б—В–≤–Њ

|

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є

|

–Я–ї–∞—Б—В–Є–Ї–Њ–≤–∞—П –Њ–њ–∞–ї—Г–±–Ї–∞

|

|

–Ф–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М

|

–Т—Л—Б–Њ–Ї–∞—П –њ—А–Њ—З–љ–Њ—Б—В—М

|

–°–Ї–ї–Њ–љ–µ–љ –Ї —А–∞—Б—В—А–µ—Б–Ї–Є–≤–∞–љ–Є—О

|

|

–У–Є–±–Ї–Њ—Б—В—М –њ—А–Є–ї–Њ–ґ–µ–љ–Є—П

|

–Ш–Ј–≥–Њ—В–Њ–≤–ї–µ–љ–Њ –љ–∞ –Ј–∞–Ї–∞–Ј

|

–Ю–≥—А–∞–љ–Є—З–µ–љ–љ–Њ–µ –Ї–Њ–ї–Є—З–µ—Б—В–≤–Њ –≤–∞—А–Є–∞–љ—В–Њ–≤ –њ–ї–∞–љ–Є—А–Њ–≤–Ї–Є

|

|

–Ь–∞—Б—И—В–∞–±–Є—А—Г–µ–Љ–Њ—Б—В—М

|

–Ы–µ–≥–Ї–Њ –Љ–∞—Б—И—В–∞–±–Є—А—Г–µ—В—Б—П

|

–Ю–≥—А–∞–љ–Є—З–µ–љ–љ–∞—П –≤–Њ–Ј–Љ–Њ–ґ–љ–Њ—Б—В—М –њ–Њ–≤—В–Њ—А–љ–Њ–≥–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П

|

–Х—Б–ї–Є –≤–∞–Љ –љ—Г–ґ–љ—Л –і–Њ–ї–≥–Њ–≤–µ—З–љ—Л–µ –Љ–∞—В–µ—А–Є–∞–ї—Л, –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—Й–Є–µ –≥–Є–±–Ї–Њ—Б—В—М –і–Є–Ј–∞–є–љ–∞ –Є –Љ–∞—Б—И—В–∞–±–Є—А—Г–µ–Љ–Њ—Б—В—М, –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є вАФ —А–∞–Ј—Г–Љ–љ—Л–є –≤—Л–±–Њ—А. –Т–Њ—В —З—В–Њ –≤–∞–Љ —Б–ї–µ–і—Г–µ—В —Б–і–µ–ї–∞—В—М –і–∞–ї—М—И–µ:

-

–Ю–њ—А–µ–і–µ–ї–Є—В–µ –њ–Њ—В—А–µ–±–љ–Њ—Б—В–Є –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞ –Є –≤—Л–±–µ—А–Є—В–µ –њ–Њ–і—Е–Њ–і—П—Й–Є–є —Б–њ–ї–∞–≤.

-

–Т—Л–±–µ—А–Є—В–µ —Д–Њ—А–Љ—Г –њ—А–Њ—Д–Є–ї—П –Є –Њ—В–і–µ–ї–Ї—Г, –Ї–Њ—В–Њ—А—Л–µ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤—Г—О—В –≤–∞—И–µ–Љ—Г —Б—В–Є–ї—О.

-

–°—А–∞–≤–љ–Є—В–µ —Ж–µ–љ—Л –Є –Ј–∞–њ—А–Њ—Б–Є—В–µ –Њ–±—А–∞–Ј—Ж—Л.

-

–Я–Њ–≥–Њ–≤–Њ—А–Є—В–µ —Б —Н–Ї—Б–њ–µ—А—В–∞–Љ–Є –Є –Є–Ј—Г—З–Є—В–µ –њ–Њ—Б—В–∞–≤—Й–Є–Ї–Њ–≤, —З—В–Њ–±—Л –≤—Л–±—А–∞—В—М –Ї–∞—З–µ—Б—В–≤–µ–љ–љ—Л–є —В–Њ–≤–∞—А –Є –Њ–±–µ—Б–њ–µ—З–Є—В—М –Є–љ–і–Є–≤–Є–і—Г–∞–ї—М–љ—Г—О –љ–∞—Б—В—А–Њ–є–Ї—Г.

–Я—А–Є –Ї–Њ–љ—Б—Г–ї—М—В–∞—Ж–Є–Є —Б –њ–Њ—Б—В–∞–≤—Й–Є–Ї–∞–Љ–Є, –њ–Њ–Є–љ—В–µ—А–µ—Б—Г–є—В–µ—Б—М –њ—А–Њ–≤–µ—А–Ї–Њ–є —Б—Л—А—М—П, –Ї–Њ–љ—В—А–Њ–ї–µ–Љ –Ї–∞—З–µ—Б—В–≤–∞ –љ–∞ –≤—Б–µ—Е —Н—В–∞–њ–∞—Е –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–∞ –Є –Ј–∞–Ї–ї—О—З–Є—В–µ–ї—М–љ—Л–Љ–Є –∞—Г–і–Є—В–∞–Љ–Є. –≠—В–Є —И–∞–≥–Є –њ–Њ–Љ–Њ–≥—Г—В –≤–∞–Љ –≤—Л–±—А–∞—В—М –ї—Г—З—И–Є–є –∞–ї—О–Љ–Є–љ–Є–є –і–ї—П –≤–∞—И–µ–≥–Њ –њ—А–Њ–µ–Ї—В–∞. –Т—Л —Б–і–µ–ї–∞–µ—В–µ –±–Њ–ї–µ–µ –њ—А–∞–≤–Є–ї—М–љ—Л–є –≤—Л–±–Њ—А, –µ—Б–ї–Є –±—Г–і–µ—В–µ –њ–Њ–і–±–Є—А–∞—В—М –Љ–∞—В–µ—А–Є–∞–ї—Л –≤ —Б–Њ–Њ—В–≤–µ—В—Б—В–≤–Є–Є —Б –≤–∞—И–Є–Љ–Є —В—А–µ–±–Њ–≤–∞–љ–Є—П–Љ–Є –Є —Б–Њ—В—А—Г–і–љ–Є—З–∞—В—М —Б –њ—А–Њ—Д–µ—Б—Б–Є–Њ–љ–∞–ї–∞–Љ–Є.

–І–∞—Б—В–Њ –Ј–∞–і–∞–≤–∞–µ–Љ—Л–µ –≤–Њ–њ—А–Њ—Б—Л

–Я–Њ—З–µ–Љ—Г –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є —П–≤–ї—П—О—В—Б—П —Е–Њ—А–Њ—И–Є–Љ –≤—Л–±–Њ—А–Њ–Љ –і–ї—П —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л—Е –њ—А–Њ–µ–Ї—В–Њ–≤?

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ–±–µ—Б–њ–µ—З–Є–≤–∞—О—В –ї–µ–≥–Ї–Њ—Б—В—М, –њ—А–Њ—З–љ–Њ—Б—В—М, –њ—А–Њ—Б—В–Њ—В—Г –Љ–Њ–љ—В–∞–ґ–∞ –Є –≥–Є–±–Ї–Њ—Б—В—М –і–Є–Ј–∞–є–љ–∞. –Т—Л –Љ–Њ–ґ–µ—В–µ –≤—Л–±—А–∞—В—М –Є–Ј –Љ–љ–Њ–ґ–µ—Б—В–≤–∞ –≤–∞—А–Є–∞–љ—В–Њ–≤ –Њ—В–і–µ–ї–Ї–Є –Є —Д–Њ—А–Љ. –Ъ—А–Њ–Љ–µ —В–Њ–≥–Њ, –≤—Л –њ–Њ–ї—Г—З–∞–µ—В–µ –і–Њ–ї–≥–Њ–≤–µ—З–љ–Њ—Б—В—М –Є –љ–Є–Ј–Ї–Є–µ –Ј–∞—В—А–∞—В—Л –љ–∞ —В–µ—Е–љ–Є—З–µ—Б–Ї–Њ–µ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ.

–Ь–Њ–ґ–љ–Њ –ї–Є –њ–µ—А–µ—А–∞–±–∞—В—Л–≤–∞—В—М –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –њ–Њ—Б–ї–µ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П?

–Ф–∞! –Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –њ–Њ—З—В–Є –љ–∞ 100% –њ–Њ–і–ї–µ–ґ–∞—В –њ–µ—А–µ—А–∞–±–Њ—В–Ї–µ. –Т—Л–±–Є—А–∞—П –∞–ї—О–Љ–Є–љ–Є–є, –≤—Л –њ–Њ–Љ–Њ–≥–∞–µ—В–µ –Њ–Ї—А—Г–ґ–∞—О—Й–µ–є —Б—А–µ–і–µ. –Я–µ—А–µ—А–∞–±–Њ—В–Ї–∞ –∞–ї—О–Љ–Є–љ–Є—П —В—А–µ–±—Г–µ—В –Љ–µ–љ—М—И–µ —Н–љ–µ—А–≥–Є–Є, —З–µ–Љ –њ—А–Њ–Є–Ј–≤–Њ–і—Б—В–≤–Њ –љ–Њ–≤–Њ–≥–Њ –Љ–∞—В–µ—А–Є–∞–ї–∞.

–І–µ–Љ –Њ—В–ї–Є—З–∞—О—В—Б—П –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ—В —Б—В–∞–ї—М–љ—Л—Е –њ—А–Є –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є–Є –љ–∞ –Њ—В–Ї—А—Л—В–Њ–Љ –≤–Њ–Ј–і—Г—Е–µ?

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Њ–±–ї–∞–і–∞—О—В –ї—Г—З—И–µ–є –Ї–Њ—А—А–Њ–Ј–Є–Њ–љ–љ–Њ–є —Б—В–Њ–є–Ї–Њ—Б—В—М—О, —З–µ–Љ —Б—В–∞–ї—М–љ—Л–µ. –Ю–љ–Є —В—А–µ–±—Г—О—В –Љ–µ–љ—М—И–µ –≤—А–µ–Љ–µ–љ–Є –љ–∞ –Њ–±—Б–ї—Г–ґ–Є–≤–∞–љ–Є–µ. –Р–ї—О–Љ–Є–љ–Є–є —Е–Њ—А–Њ—И–Њ –њ–Њ–і—Е–Њ–і–Є—В –і–ї—П –Њ–Ї–Њ–љ, –і–≤–µ—А–µ–є –Є –љ–∞–≤–µ—Б–љ—Л—Е —Б—В–µ–љ –≤ —Г—Б–ї–Њ–≤–Є—П—Е –љ–∞—А—Г–ґ–љ–Њ–≥–Њ –њ—А–Є–Љ–µ–љ–µ–љ–Є—П.

–С–µ–Ј–Њ–њ–∞—Б–љ—Л –ї–Є –∞–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –і–ї—П –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞–љ–Є—П –≤ —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л—Е –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є—П—Е?

–Р–ї—О–Љ–Є–љ–Є–µ–≤—Л–µ –њ—А–Њ—Д–Є–ї–Є –Љ–Њ–ґ–љ–Њ –Є—Б–њ–Њ–ї—М–Ј–Њ–≤–∞—В—М –≤ —Б–∞–Љ—Л—Е —А–∞–Ј–љ—Л—Е –Ї–Њ–љ—Б—В—А—Г–Ї—Ж–Є—П—Е. –Ю–љ–Є –Њ–±–ї–∞–і–∞—О—В –≤—Л—Б–Њ–Ї–Є–Љ —Б–Њ–Њ—В–љ–Њ—И–µ–љ–Є–µ–Љ –њ—А–Њ—З–љ–Њ—Б—В–Є –Ї –≤–µ—Б—Г. –Ш—Е –Љ–Њ–ґ–љ–Њ –≤—Б—В—А–µ—В–Є—В—М –≤ –Ї–∞—А–Ї–∞—Б–∞—Е –Ј–і–∞–љ–Є–є, —Б—В—А–Њ–Є—В–µ–ї—М–љ—Л—Е –ї–µ—Б–∞—Е –Є –њ—А–Њ–Љ—Л—И–ї–µ–љ–љ–Њ–Љ –Њ–±–Њ—А—Г–і–Њ–≤–∞–љ–Є–Є.

English

English  fran√Іais

fran√Іais  Deutsch

Deutsch  —А—Г—Б—Б–Ї–Є–є

—А—Г—Б—Б–Ї–Є–є  espa√±ol

español  português

portugu√™s  ЎІўДЎєЎ±Ў®ўКЎ©

ЎІўДЎєЎ±Ў®ўКЎ©  Melayu

Melayu  аєДаЄЧаЄҐ

аєДаЄЧаЄҐ  Indonesia

Indonesia  а§єа§ња§В৶а•А

а§єа§ња§В৶а•А

–Я–Њ–і–і–µ—А–ґ–Є–≤–∞–µ—В—Б—П —Б–µ—В—М IPv6

–Я–Њ–і–і–µ—А–ґ–Є–≤–∞–µ—В—Б—П —Б–µ—В—М IPv6