Когда вы начинаете планировать свой проект, вы хотите убедиться, что выбрали правильный Индивидуальный алюминиевый профиль . Сначала подумайте о том, что нужно вашему проекту. Этот шаг поможет вам избежать ошибок в дальнейшем. Спросите себя, для чего он будет использоваться. Подумайте, какую нагрузку должен выдерживать профиль и в каких условиях он будет работать.

Зная свои потребности, вы сможете выбрать лучший алюминиевый сплав и форму.

При выборе учитываются весовая поддержка и условия окружающей среды.

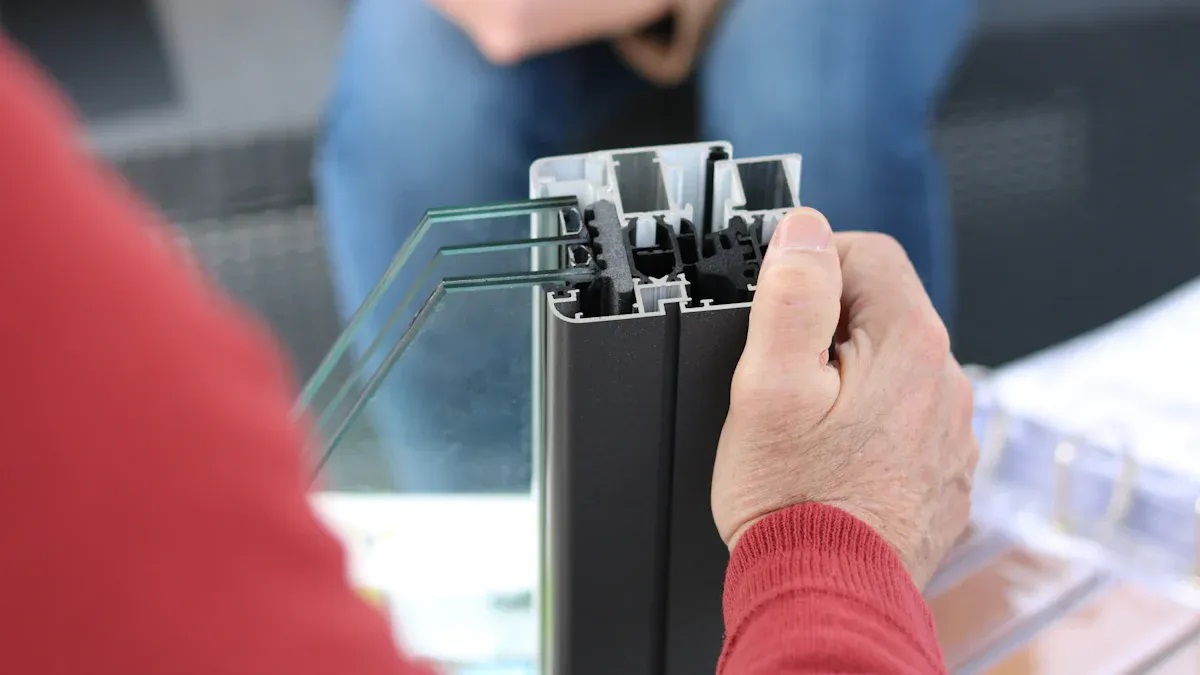

Точные измерения, такие как толщина стенок и поперечное сечение, гарантируют, что все будет хорошо подходить и работать.

Уделив время выяснению этих вопросов, вы значительно облегчите весь остальной процесс.

Прежде чем выбрать алюминиевый профиль, подумайте о том, что нужно вашему проекту. Учтите, как вы будете его использовать, какой вес он должен выдерживать и где он будет использоваться.

Выберите оптимальный алюминиевый сплав и форму профиля в зависимости от предполагаемого веса. Сплавы обладают разной прочностью и сроком службы.

Тщательно измерьте толщину и сечение стенки, чтобы всё подошло идеально. Это поможет избежать проблем при установке.

Выберите правильную отделку поверхности, чтобы профиль прослужил дольше и выглядел лучше. Наиболее распространённые варианты — анодирование и порошковое покрытие.

Проверьте поставщиков, обратив внимание на то, как они обеспечивают качество своей продукции и как помогают с индивидуальными заказами. Хороший поставщик может способствовать успеху вашего проекта.

Прежде чем выбрать индивидуальный алюминиевый профиль, подумайте о требованиях вашего проекта. Это поможет вам избежать проблем в будущем. Давайте рассмотрим, что следует учесть.

Спросите себя: «Для чего я буду использовать этот профиль?» Тип применения влияет на каждый ваш последующий выбор. Делаете ли вы каркас для машины, полку или часть здания? Для каждого варианта применения свои требования.

Вот краткий обзор областей применения изготовленных на заказ алюминиевых профилей:

|

Область применения |

Описание |

|---|---|

|

Промышленная автоматизация |

Используется в машинах, которые передвигаются самостоятельно, а также на заводах. |

|

Структурные применения |

Каркасы для автомобилей, продукции и экологичных зданий. |

|

Снижение веса |

Выбирается, когда вам нужны прочные, но легкие детали. |

|

Механическое оборудование |

Встречается в конвейерных лентах, подъемниках и испытательных машинах. |

|

Безопасность Защита |

Защищает людей и оборудование в оживленных рабочих зонах. |

Эти профили можно найти в школах и больницах. Они также используются в зданиях, где важны дизайн и функциональность. Изготовленные на заказ алюминиевые профили позволяют выбрать нужную форму и размер. Вы можете выбрать что-то стильное или очень прочное.

Кончик: Подумайте, насколько легко установить и отремонтировать профиль. Некоторые алюминиевые профили значительно упрощают замену и ремонт.

Затем определите, какой вес должен выдерживать ваш профиль. Для некоторых проектов нужны профили, способные выдерживать тяжёлые нагрузки. Для других же нужно что-то лёгкое и удобное для перемещения. Необходимая прочность поможет вам выбрать правильный сплав и конструкцию.

Вот несколько примеров того, какой вес могут выдерживать профили:

Промышленный алюминиевый профиль 2020 года может выдерживать нагрузку около 20 кг.

Если добавить дополнительную поддержку, тот же профиль может выдерживать нагрузку до 40 кг.

Профиль 4545 длиной 500 мм может выдерживать нагрузку 800 Н с небольшим изгибом.

Выбор типа алюминиевого профиля имеет большое значение. Сплав играет важную роль. Например, 6063 подходит для большинства задач, но 6061 лучше подходит для тяжёлых работ. Всегда подбирайте форму и размер профиля в соответствии с весом, необходимым для вашего проекта.

Примечание: Если вы не уверены, обратитесь за помощью к поставщику. Он поможет вам выбрать профиль, соответствующий вашим потребностям.

Теперь подумайте, где вы будете использовать свой алюминиевый профиль. Будете ли вы использовать его на улице под дождём, в солёной атмосфере или в среде с химическими веществами? Окружающая среда может повлиять на срок службы и качество работы вашего профиля.

Ниже представлена таблица, показывающая, как различные факторы влияют на алюминиевые профили:

|

Фактор |

Воздействие на алюминиевые профили |

|---|---|

|

Температура |

Высокая температура может ускорить коррозию, особенно вблизи океана. |

|

Влажность |

Большое количество воды в воздухе может привести к разрушению защитного слоя и появлению трещин. |

|

Химическое воздействие |

Химикаты, такие как хлорид, могут повредить металл и сократить срок его службы. |

Если вы используете профиль снаружи или в сложных условиях, вам могут потребоваться специальные покрытия или анодирование. Они защищают от ржавчины и повреждений. В местах с высоким содержанием соли или загрязнений эти меры ещё важнее.

Помнить: Правильная отделка поверхности позволит вашему профилю выглядеть хорошо и исправно работать в течение длительного времени.

Уделяя время обдумыванию сферы применения, нагрузки и условий эксплуатации, вы обеспечиваете себе успех. Вам будет гораздо проще выбрать подходящие типы алюминиевых профилей, оптимальную форму и размер, а также подходящую отделку для вашего проекта.

При выборе алюминиевых профилей у вас есть два варианта. Один из них — стандартные профили, а другой — профили, изготовленные на заказ. Стандартные профили подходят для большинства проектов. Они доступны в различных формах и размерах. Вы легко их найдете. Изготовление алюминиевых профилей на заказ позволит вам создать что-то особенное. Возможно, вам понадобится новая форма или повышенная прочность.

Вот таблица, которая поможет вам сравнить:

|

Фактор |

||

|---|---|---|

|

Требования к заявке |

Создано для сложных проектов |

Подходит для общего использования. |

|

Эффективность затрат |

Сначала дороже из-за дизайна и инструментов |

Дешевле и проще найти |

|

Сроки производства |

Требуется больше времени, чтобы сделать |

Быстро готов к использованию |

|

Прочность и долговечность материала |

Возможны специальные сплавы и повышенная прочность |

Сильный, но не допускается много изменений |

|

Гибкость дизайна |

Уникальные формы и особенности |

Установить размеры и формы |

Если ваш проект требует чего-то особенного, выберите алюминиевый профиль по индивидуальному заказу. Для простых задач стандартные профили экономят время и деньги.

Алюминиевые профили бывают самых разных форм и размеров. Вы можете выбрать цельные формы, такие как квадраты, прямоугольники, круглые или шестиугольные. Также распространены полые формы, например, трубы и швеллеры. Вот некоторые из них:

Трубчатые полости

Квадратные углубления

Прямоугольные углубления

Структурная труба

Алюминиевые каналы

двутавровые балки

Углы

Футболки

Зис

Бары

Каждая форма придает алюминиевому профилю разную прочность. Двутавровые балки выдерживают большие нагрузки. Т-образные пазы позволяют создавать каркасы, которые можно менять в дальнейшем. Правильная форма и размер делают ваши профили прочными и безопасными.

|

Тип профиля |

Описание |

Влияние на структурную целостность |

|---|---|---|

|

Двутавровые балки |

Используется в строительстве для прочности. |

Выдерживают большой вес и увеличивают грузоподъемность. |

|

Т-образные пазы |

Подходит для рамок, которые можно регулировать. |

Сделайте проекты более гибкими и эффективными. |

Вы хотите, чтобы ваша система алюминиевых профилей работала с правильными аксессуарами. Хорошая совместимость позволяет легко добавлять кронштейны, соединители, торцевые заглушки, петли, слайдеры и крепежные элементы. Эти детали помогут вам собрать и соединить профили.

Скобки

Разъемы

Заглушки

Петли

Ползунки

Крепеж

Выравнивающие ножки

Угловые соединения

Аксессуары подходят ко многим размерам профилей, например, к профилям серий 20, 30, 40, 45, 60 и 80. Всегда проверяйте их совместимость перед покупкой. Правильное соответствие обеспечит безопасность и устойчивость вашей системы. Неправильный выбор размера может привести к проблемам при сборке. Выбирайте аксессуары из прочных материалов для лучшей устойчивости.

Кончик: Всегда подбирайте размер аксессуара под ваш алюминиевый профиль. Это сделает ваш проект проще и безопаснее.

Выбор правильного материала и отделки очень важен. Он может изменить внешний вид и функциональность вашего проекта. Давайте рассмотрим, что вам следует знать.

Существует несколько распространённых марок алюминия для изготовления профилей по индивидуальному заказу. Каждая из них имеет свои преимущества и характеристики прочности.

6061 широко используется в строительстве и на заводах.

6063 хорош для аналогичных работ и легко поддается формовке.

Вот таблица, которая поможет вам сравнить:

|

Марка алюминия |

Прочность на растяжение (МПа) |

Коррозионная стойкость |

Стоимость (за кг) |

|---|---|---|---|

|

5052 |

220 |

Отлично, особенно в соленой воде |

1,50–3 доллара |

|

6061 |

310 |

Хорошо, широко используется в конструкциях |

1,50–3 доллара |

|

7075 |

572 |

Устойчив к химикатам и суровым условиям |

1,50–3 доллара |

Если вам нужно что-то очень прочное, выбирайте 7075. Для большинства строительных работ подойдут 6061 или 6063.

Выбранное покрытие влияет на внешний вид и срок службы вашего алюминиевого профиля. Некоторые покрытия предотвращают появление ржавчины, другие придают металлу блеск.

|

Отделка поверхности |

Преимущества |

|---|---|

|

Отделка мельницы |

Дешево и просто; выглядит некрасиво; служит недолго. |

|

Анодирование |

Останавливает ржавчину и износ; помогает при жаре; может придавать цвет. |

|

Порошковое покрытие |

Множество цветов; прочный и надежный; подходит для использования на открытом воздухе. |

|

Алодирование |

Дешевле, чем анодирование; предотвращает появление ржавчины; обеспечивает подачу электричества. |

|

Яркое погружение |

Придает металлу яркий блеск. |

|

Механическая отделка |

Делает поверхность гладкой и подготавливает ее к другим видам отделки. |

Правильная отделка продлит срок службы вашего профиля и улучшит его внешний вид. Анодирование может продлить срок службы алюминия на долгие годы. Порошковое покрытие придаёт цвет и легко ухаживать за ним. Неправильный выбор отделки может привести к ухудшению срока службы профиля и ухудшению его внешнего вида.

Кончик: Подумайте о том, как долго вы хотите, чтобы ваш алюминиевый профиль прослужил. Кроме того, прежде чем выбирать отделку, подумайте о том, где вы будете его использовать.

Вы хотите, чтобы ваш проект выглядел красиво и работал хорошо. Иногда приходится выбирать между этими двумя вещами. Вот несколько советов:

Алюминиевые профили позволяют создавать интересные проекты и при этом отлично функционировать.

Прочные профили сохранят ваш проект в безопасности в непогоду или при интенсивном использовании.

Специальная отделка может сделать ваш проект прочным и стильным.

Многим архитекторам нравятся материалы, которые могут воплотить множество идей.

|

Аспект |

Эстетика |

Функциональность |

|---|---|---|

|

Материал |

Алюминий выглядит хорошо |

Прочный и экономит энергию |

|

Гибкость дизайна |

Позволяет создавать креативные дизайны |

Соответствует потребностям вашего проекта |

|

Устойчивость |

Может быть переработан |

Долго служит. |

Выбранный вами материал и отделка определят внешний вид и прочность вашего проекта. Постарайтесь найти вариант, который соответствует вашим потребностям и бюджету.

Планируя свой проект, вы хотите контролировать расходы и бюджет. Выбор правильного алюминиевого профиля на заказ подразумевает не только цену. Необходимо учитывать факторы, влияющие на стоимость, сроки выполнения заказа и наличие ограничений по минимальному заказу.

На стоимость вашего алюминиевого профиля может влиять множество факторов. Вот таблица, которая поможет вам определить наиболее важные из них:

|

Фактор |

Описание |

|---|---|

|

Лондонская биржа металлов |

Цена на алюминий меняется каждый день в зависимости от рынка. |

|

Размер профиля |

Изготовление профилей большего или меньшего размера может обойтись дороже. |

|

Стоимость штампа |

Изготовление нового штампа для вашей формы влечет за собой единовременные затраты. |

|

Вес на метр |

Более тяжелые профили используют больше металла, поэтому они стоят дороже. |

|

Умный дизайн |

Умные проекты могут сэкономить деньги, сократив объем дополнительной работы. |

|

Размер заказа |

Более крупные заказы обычно означают более низкую стоимость за штуку. |

|

Стоимость отделки |

Специальные виды отделки, такие как порошковое покрытие или анодирование, увеличивают стоимость. |

Выбор материала также влияет на стоимость. Некоторые сплавы проще в обработке и дешевле. Если ваш дизайн сложный, изготовление может потребовать больше времени и специальных инструментов, что может увеличить стоимость. Заказ большего количества изделий за один раз поможет снизить цену каждого изделия.

Вы хотите знать, сколько времени займёт изготовление ваших профилей. Изготовление профилей по индивидуальному заказу занимает больше времени, поскольку заводу необходимо изготовить новую оснастку. Стандартные профили изготавливаются быстрее, поскольку они готовы к использованию. Вот краткий обзор сроков изготовления некоторых профилей:

|

Тип профиля |

Срок поставки (недели) |

|---|---|

|

Трубы алюминиевые бесшовные тянутые |

50-60 |

|

Конструкционные прессованные изделия из сплавов 7xx и 2xx |

25-30 |

|

Вытянутая трубка иллюминатора |

12-14 |

Индивидуальные профили требуют больше времени на проектирование и настройку. Изготовление штампа может занять от 2 до 4 недель. Если форма сложная, это может занять ещё больше времени. Всегда планируйте заранее, чтобы ваш проект не сбивал с пути, не выходил за рамки бюджета и затрат.

Кончик: Перед заказом уточните у поставщика сроки поставки. Это поможет вам избежать задержек.

У некоторых поставщиков есть свои правила относительно объёма закупки. Например, Profall требует не менее 200 кг на заказ. Некоторые компании позволяют заказывать меньше, что отлично подходит для небольших проектов или прототипов.

|

Поставщик |

Минимальное количество заказа |

Срок поставки |

|---|---|---|

|

Профол |

200 кг |

2 недели |

|

Алюминиевые профили |

Нет строгого минимума |

Н/Д |

|

Chalco Алюминий |

Н/Д |

Н/Д |

Если вам нужно всего несколько штук, ищите поставщиков без минимального заказа. Так вы сэкономите деньги и избежите скопления лишних запасов. Для крупных проектов более крупные заказы могут помочь вам получить более выгодную цену.

Помнить: Баланс качества, стоимости и бюджета поможет вашему проекту добиться успеха. Всегда проверяйте детали перед покупкой.

Выбор правильного поставщика очень важен. Выбранный вами поставщик может помочь вашему проекту или создать проблемы. Вам нужен партнёр, который заботится о качестве и учитывает индивидуальные потребности. Он также должен помочь вам избежать ошибок. Вот на что следует обратить внимание, прежде чем принять решение.

Хотите, чтобы ваш проект прослужил долго? Всегда спрашивайте, как поставщик проверяет качество. Хорошие поставщики проверяют качество на каждом этапе. Они проверяют сырье и процесс экструзии. Они также тестируют готовую продукцию. Обратите внимание на следующие этапы:

Проверка сырья

Управление процессом экструзии

Проверка размеров профиля

Оценка качества поверхности

Испытание механических свойств

Окончательная проверка упаковки

Эти шаги помогут вам убедиться в качестве ваших алюминиевых профилей. Если поставщик пропустит какой-либо этап, ваш проект может столкнуться с проблемами.

Каждый проект уникален. Вам могут потребоваться специальные профили или функции. Хороший поставщик поможет с проектированием и разработкой. Он также поможет с контролем качества. Эффективная поддержка кастомизации поможет вашему проекту во многих отношениях.

|

Мера контроля качества |

Влияние на результаты проекта |

|---|---|

|

Строгий отбор материалов |

Сохраняет ваши профили прочными и долговечными. |

|

Передовой дизайн и проектирование |

Помогает обнаружить проблемы до начала производства. |

|

Высокоточное производство |

Убедитесь, что ваши профили точно соответствуют вашему дизайну. |

|

Контроль качества в процессе производства |

Выявляем ошибки на ранней стадии, благодаря чему вы получаете правильный тип алюминиевого профиля. |

|

Постпроизводственное тестирование |

Проверяет, соответствуют ли ваши профили всем требованиям качества. |

|

Сотрудничество с клиентами |

Позволяет вам создавать индивидуальные планы для успеха вашего проекта. |

Сотрудничество с поставщиком, предлагающим широкие возможности кастомизации, упрощает задачу. Ваш проект будет реализован более гладко и качественно.

Прежде чем выбрать поставщика, воспользуйтесь этим контрольным списком. Он поможет вам сделать правильный выбор:

Имеет ли поставщик строгий процесс контроля качества?

Могут ли они удовлетворить ваши индивидуальные потребности?

Помогают ли они после продажи?

Подходят ли вам сроки доставки и минимальные заказы?

Есть ли у них опыт работы с проектами, подобными вашему?

Кончик: Запросите образцы или рекомендации с других проектов. Это поможет вам убедиться в высоком качестве.

Многие совершают одни и те же ошибки при выборе профилей. Вот несколько распространённых ошибок и способы их избежать:

|

Ошибка |

Описание |

|---|---|

|

Выбор неправильного стандарта |

Смешение китайских и европейских стандартов может привести к формированию неправильного профиля вашего проекта. |

|

Игнорирование несущей способности |

Невыполнение проверки того, какой вес должен выдерживать ваш профиль, может привести к серьезным проблемам. |

|

Неспособность различать типы |

Выбор легкого профиля для тяжелой работы может означать, что ваш проект окажется недостаточно безопасным или прочным. |

Чтобы избежать этих ошибок, всегда:

Проверьте допуски заранее и при необходимости обратитесь к экспертам.

Для лучшего выдавливания используйте закругленные углы вместо острых.

Создавайте профили, которые легко собирать.

Постарайтесь сделать свой дизайн сбалансированным и ровным.

Следуя этим шагам, вы выберете правильный алюминиевый профиль. У вашего проекта будет больше шансов на успех.

Теперь вы знаете, как выбрать подходящий алюминиевый профиль для вашего проекта. Начните с анализа ваших потребностей. Учитывайте область применения, нагрузку и окружающую среду. Выберите оптимальную марку алюминия и отделку для вашего проекта. Убедитесь, что алюминиевый профиль соответствует вашему бюджету. Если у вас есть вопросы, обратитесь к поставщикам или экспертам. Они помогут вам подобрать идеальный алюминиевый профиль. Готовы начать? Свяжитесь с нами сегодня, чтобы получить дополнительную информацию или поддержку!